Difference between revisions of "Toe alignment using straight edges"

EliseS1 man (talk | contribs) |

EliseS1 man (talk | contribs) |

||

| (38 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

== A simple method for checking front and rear toe alignment == | == A simple method for checking front and rear toe alignment == | ||

| − | To enjoy the benefit of | + | To enjoy the benefit of Lotus suspension and its cornering ability it is important that the wheels actually point in the direction that Lotus intended. |

The "string method" for checking toe settings is well known and described in this forum. | The "string method" for checking toe settings is well known and described in this forum. | ||

| Line 9: | Line 9: | ||

What you will need are these simple tools: | What you will need are these simple tools: | ||

| − | + | # Two 4 meter long builders straight edges | |

| + | # Four 5 liter sprinkler fluid bottles | ||

| − | + | And the setup is this simple: | |

| − | + | [[File:Straight_edge_left.jpg]] [[File:Straight_edge_right.jpg]] | |

| − | [[File: | + | The sprinkler bottles are placed up against each wheel. The straight edges are placed lying down on top of the sprinkler bottles and the straight edges touches the sidewall of the tyres. |

| + | The ends of the straight edges should overhang the front and the rear of the car. | ||

| + | |||

| + | Common 5 liter sprinkler fluid bottles are ideal as they are suitably heavy when filled with fluid, they are level on top and their height conveniently matches the center height of the wheels. | ||

| + | |||

| + | Any material for the straight edges can be used as long as they are straight and don’t bend. It is easy to check edges against one another; turn them round and recheck, they should not show any gaps or twists. Builders straight edges can be bought from builder’s material markets and there are lots to pick from on the internet. I used SVALK aluminum extrusions of 18 x 100 mm, but any sensible straight and stiff ones will do. | ||

| + | |||

| + | Placed against the tyre sidewalls the straight edges are not parallel and do actually toe-in a little. | ||

| + | So we will have to quantify the amount of toe-in of the straight edges which of course will be our references. | ||

| + | |||

| + | An Elise S1 and the 340R toe requirements are used in this example but you can edit the numbers below with you cars requirements. | ||

| + | |||

| + | The distance between the straight edges front and rear is measured as well as the length of the straight edges. | ||

| + | From the drawing below you can see the measurements obtained from a car with standard rims and standard tyre dimensions. | ||

| + | |||

| + | [[File:Measuring_straight_edge_at_tyre_sides-komp.JPG]] | ||

| + | |||

| + | The amount of total toe-in of the straight edges can now be calculated to: 1883-1823=60 mm | ||

| + | |||

| + | [[File:Toe_triangle.JPG]] | ||

| + | |||

| + | So in relation to the car centerline each straight edge has an individual toe-in of: 60/2=30 mm | ||

| + | |||

| + | The toe-in of each straight edge can therefore be calculated to: 30/3998=1/133 mm ⁄ mm | ||

| + | |||

| + | This means that for every mm you go forward along the straight it goes inwards by 1/133 mm. | ||

| + | |||

| + | This is useful when we check the alignment with the straight edges against the requirements set up by Lotus for the toe of the rear and front wheels: | ||

| + | |||

| + | In this case the car is set up with the 340R-settings for track use and they are according to the Lotus service notes: | ||

| + | |||

| + | [[File:Lotus_rear_toe-komp.JPG]] [[File:Lotus_front_toe-komp.JPG]] | ||

| + | |||

| + | So we have | ||

| + | |||

| + | Rear: 2.5 mm toe-in each side; + 0.2, - 0 measured on a 16” rim. | ||

| + | Front: 0.5 mm toe-out overall; +0.2, - 0 measured on the 15” rim. | ||

| + | |||

| + | which translates to individual wheel settings of | ||

| + | |||

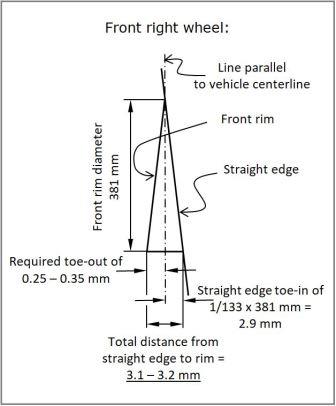

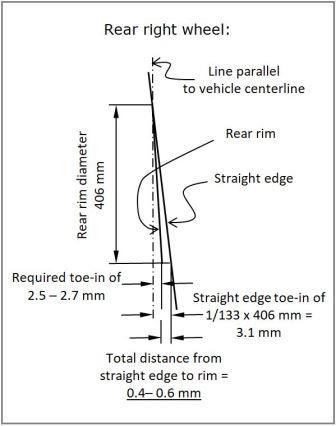

| + | Rear: From 2.5 mm to 2.7 mm toe-in each side measured on a 406 mm diameter rim. | ||

| + | Front: From 0.25 mm to 0.35 mm toe-out each side on a 381 mm diameter rim. | ||

| + | |||

| + | |||

| + | '''Toe measured on rim diameter:''' | ||

| + | |||

| + | Locally at each wheel rim we have this situation in relation to the straight edge each side: | ||

| + | |||

| + | [[File:Front_right_wheel_distance-komp.JPG]] | ||

| + | |||

| + | [[File:Right_rear_wheel_distance-komp.JPG]] | ||

| + | |||

| + | The depth gauge of an electronic caliper can be used to measure distance from straight edge to rim fore and aft on the rim and the difference is the toe. You can even zero the caliper on the measurement fore and then you have the resulting toe when you measure aft on the rim. | ||

| + | |||

| + | |||

| + | '''Toe measured on tyre wall diameter:''' | ||

| + | |||

| + | As the straight edges touch the tyre sidewalls front and rear it is convenient to reduce the task to check the gap from the tyre sidewall to the straight edge. | ||

| + | That requires a translation of the required distances measured at rim diameter to distance measured on tyre sidewall diameter: | ||

| + | |||

| + | |||

| + | <u>Front:</u> | ||

| + | Gap to straight edge measured on | ||

| + | rearmost sidewall of 485 mm diameter: | ||

| + | (3.1→3.2)∙485/381 = <u>3.9 → 4.1 mm</u> | ||

| + | |||

| + | Note the white 4 mm plastic block between rear sidewall and straight edge used for checking gap. | ||

| + | |||

| + | [[File:Front_left.jpg]] | ||

| + | |||

| + | |||

| + | <u>Rear:</u> | ||

| + | Gap to straight edge measured on rearmost sidewall of 510 mm diameter: | ||

| + | (0.4→0.6)∙510/406 = <u>0.5 → 0.8 mm</u> | ||

| + | |||

| + | Note the grey ½ mm plastic foil between rear sidewall and straight edge used for checking gap. | ||

| + | |||

| + | [[File:Toe_rear.jpg]] | ||

| + | |||

| + | |||

| + | Now the task of checking toe on wheels front and rear is reduced to putting two straight edges along the tyre sidewalls each side and measure gap from rearmost tyre wall to straight edge. So if one has a gap of front 3.9 to 4.1 mm and rear 0.5 to 0.8 mm in this case one is good to go. | ||

| + | |||

| + | |||

| + | Tip 1: Pieces of plastic foil or plastic blocks used for supporting thermo glass in window frames are available in the required thicknesses and are handy and tyre friendly when measuring toe gaps. | ||

| + | |||

| + | Tip 2: Tyre side walls do not always run true. Repeat the gap measurements four times with the car pushed forward ¼ of a wheel revolution in between measurements and take the average of your readings. | ||

| + | |||

| + | |||

| + | Hope you will enjoy the described cheap and adequately precise geo tool! | ||

| + | |||

| + | [[Category:Suspension]] | ||

| + | [[Category:Lotus Elise]] | ||

| + | [[Category:S1]] | ||

Latest revision as of 20:26, 19 April 2020

A simple method for checking front and rear toe alignment

To enjoy the benefit of Lotus suspension and its cornering ability it is important that the wheels actually point in the direction that Lotus intended.

The "string method" for checking toe settings is well known and described in this forum.

However I have found that using straight edges can be a little easier to set up and handle if you add a few easy measurements and calculations.

What you will need are these simple tools:

- Two 4 meter long builders straight edges

- Four 5 liter sprinkler fluid bottles

And the setup is this simple:

The sprinkler bottles are placed up against each wheel. The straight edges are placed lying down on top of the sprinkler bottles and the straight edges touches the sidewall of the tyres. The ends of the straight edges should overhang the front and the rear of the car.

Common 5 liter sprinkler fluid bottles are ideal as they are suitably heavy when filled with fluid, they are level on top and their height conveniently matches the center height of the wheels.

Any material for the straight edges can be used as long as they are straight and don’t bend. It is easy to check edges against one another; turn them round and recheck, they should not show any gaps or twists. Builders straight edges can be bought from builder’s material markets and there are lots to pick from on the internet. I used SVALK aluminum extrusions of 18 x 100 mm, but any sensible straight and stiff ones will do.

Placed against the tyre sidewalls the straight edges are not parallel and do actually toe-in a little. So we will have to quantify the amount of toe-in of the straight edges which of course will be our references.

An Elise S1 and the 340R toe requirements are used in this example but you can edit the numbers below with you cars requirements.

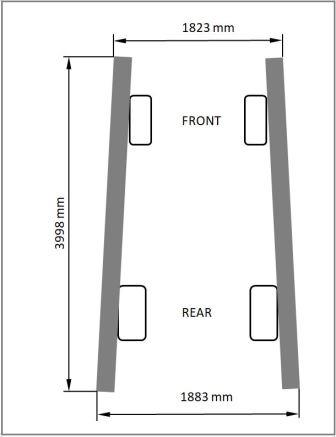

The distance between the straight edges front and rear is measured as well as the length of the straight edges. From the drawing below you can see the measurements obtained from a car with standard rims and standard tyre dimensions.

The amount of total toe-in of the straight edges can now be calculated to: 1883-1823=60 mm

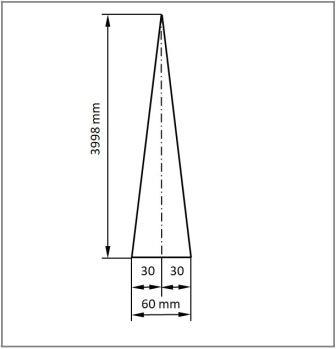

So in relation to the car centerline each straight edge has an individual toe-in of: 60/2=30 mm

The toe-in of each straight edge can therefore be calculated to: 30/3998=1/133 mm ⁄ mm

This means that for every mm you go forward along the straight it goes inwards by 1/133 mm.

This is useful when we check the alignment with the straight edges against the requirements set up by Lotus for the toe of the rear and front wheels:

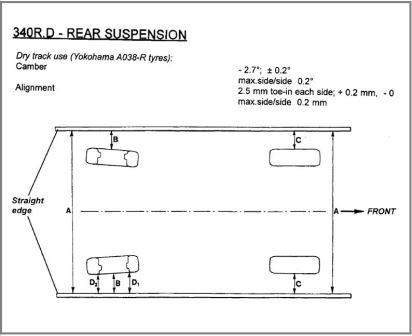

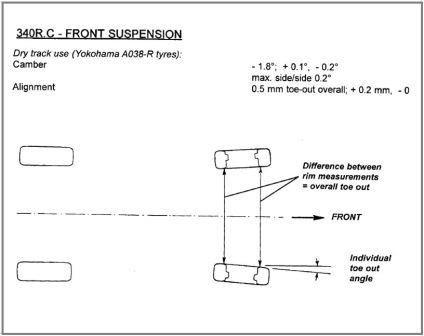

In this case the car is set up with the 340R-settings for track use and they are according to the Lotus service notes:

So we have

Rear: 2.5 mm toe-in each side; + 0.2, - 0 measured on a 16” rim. Front: 0.5 mm toe-out overall; +0.2, - 0 measured on the 15” rim.

which translates to individual wheel settings of

Rear: From 2.5 mm to 2.7 mm toe-in each side measured on a 406 mm diameter rim. Front: From 0.25 mm to 0.35 mm toe-out each side on a 381 mm diameter rim.

Toe measured on rim diameter:

Locally at each wheel rim we have this situation in relation to the straight edge each side:

The depth gauge of an electronic caliper can be used to measure distance from straight edge to rim fore and aft on the rim and the difference is the toe. You can even zero the caliper on the measurement fore and then you have the resulting toe when you measure aft on the rim.

Toe measured on tyre wall diameter:

As the straight edges touch the tyre sidewalls front and rear it is convenient to reduce the task to check the gap from the tyre sidewall to the straight edge. That requires a translation of the required distances measured at rim diameter to distance measured on tyre sidewall diameter:

Front:

Gap to straight edge measured on

rearmost sidewall of 485 mm diameter:

(3.1→3.2)∙485/381 = 3.9 → 4.1 mm

Note the white 4 mm plastic block between rear sidewall and straight edge used for checking gap.

Rear:

Gap to straight edge measured on rearmost sidewall of 510 mm diameter:

(0.4→0.6)∙510/406 = 0.5 → 0.8 mm

Note the grey ½ mm plastic foil between rear sidewall and straight edge used for checking gap.

Now the task of checking toe on wheels front and rear is reduced to putting two straight edges along the tyre sidewalls each side and measure gap from rearmost tyre wall to straight edge. So if one has a gap of front 3.9 to 4.1 mm and rear 0.5 to 0.8 mm in this case one is good to go.

Tip 1: Pieces of plastic foil or plastic blocks used for supporting thermo glass in window frames are available in the required thicknesses and are handy and tyre friendly when measuring toe gaps.

Tip 2: Tyre side walls do not always run true. Repeat the gap measurements four times with the car pushed forward ¼ of a wheel revolution in between measurements and take the average of your readings.

Hope you will enjoy the described cheap and adequately precise geo tool!