Difference between revisions of "Change a ball joint and a damper"

m |

|||

| (30 intermediate revisions by 4 users not shown) | |||

| Line 2: | Line 2: | ||

This procedure details how to change the offside lower front ball joint and damper assembly. The nearside front is an identical procedure and the upper front ball joints follow a similar procedure. The rear ball joint and damper replacement are slightly more complicated as they require a different method to remove the brake calipers. | This procedure details how to change the offside lower front ball joint and damper assembly. The nearside front is an identical procedure and the upper front ball joints follow a similar procedure. The rear ball joint and damper replacement are slightly more complicated as they require a different method to remove the brake calipers. | ||

| + | |||

| + | '''Safety Notice: | ||

| + | I did not use a fixed support to prevent the car from dropping if the trolley jack hydraulics failed when performing this procedure. It is far safer to jack up the car and then use an appropriate fixed support that cannot collapse before performing these steps.''' | ||

Step 1. Measure the height of the lower wishbone. You will need to use this measurement at step 28 when you torque up the upper and lower damper bolts (later stage of this procedure). | Step 1. Measure the height of the lower wishbone. You will need to use this measurement at step 28 when you torque up the upper and lower damper bolts (later stage of this procedure). | ||

| − | + | [[Image:2._Measuring_Lower_Wishbone_Height.JPG]] | |

| − | + | ||

| + | |||

Step 2. Loosen the bolts on the road wheel | Step 2. Loosen the bolts on the road wheel | ||

| − | + | [[Image:3._Loosening_Road_Wheel_Bolts.JPG]] | |

| − | + | ||

Step 3. Jack up the car on the front jacking point using a trolley jack and remove the front road wheel. | Step 3. Jack up the car on the front jacking point using a trolley jack and remove the front road wheel. | ||

| − | + | '''Safety Notice:''' It would be much safer to use the rear jacking point to raise the car and then place a fixed support under the front jacking point and lower the jack to use the fixed support for the car. | |

| − | + | ||

| + | [[Image:4._Road_Wheel_Removed.JPG]] | ||

Step 4. Remove the brake pipe clamp. | Step 4. Remove the brake pipe clamp. | ||

| − | + | [[Image:5._Removing_Brake_Pipe_Clamp.JPG]] | |

| + | |||

| − | Step 5. Remove the brake caliper using an 8mm hex driver or allen key. | + | Step 5. Remove the brake caliper using an 8mm hex driver or allen key and then remove the rotor. |

| + | |||

| + | [[Image:6._Removing_Front_Brake_Caliper.JPG]] | ||

| − | |||

Step 6. Secure the brake caliper so that it does not get in the way of removing the ball joint. Ensure that the brake line is not under strain and taking the weight of the caliper. You may wish to use a cable tie to secure the caliper out of the way. | Step 6. Secure the brake caliper so that it does not get in the way of removing the ball joint. Ensure that the brake line is not under strain and taking the weight of the caliper. You may wish to use a cable tie to secure the caliper out of the way. | ||

| − | + | [[Image:7._Securing_Front_Brake_Caliper.JPG]] | |

| + | |||

Step 7. Remove the ball joint nut . Use a 19mm ring/open ended spanner for the lower ball joint. You need to start with the ring end and transfer to the open end after winding the nut half the way up, otherwise the ring spanner will get stuck between the nut and the hub carrier and you won’t be able to remove the nut or the spanner. | Step 7. Remove the ball joint nut . Use a 19mm ring/open ended spanner for the lower ball joint. You need to start with the ring end and transfer to the open end after winding the nut half the way up, otherwise the ring spanner will get stuck between the nut and the hub carrier and you won’t be able to remove the nut or the spanner. | ||

| − | + | [[Image:8._Removing_Lower_Ball_Joint_Nut.JPG]] | |

| + | |||

Step 8. Split the ball joint from the hub carrier. You may wish to use a fork splitter with a few hard hits with a club hammer. Alternatively you could use a scissor splitter. | Step 8. Split the ball joint from the hub carrier. You may wish to use a fork splitter with a few hard hits with a club hammer. Alternatively you could use a scissor splitter. | ||

| − | + | [[Image:9._Splitting_Lower_Ball_Joint.JPG]] | |

| + | |||

Step 9. When the ball joint is split from the hub carrier move carrier out of the way. You could use a trolley jack handle as a prop for the hub carrier under the track rod end bolt. | Step 9. When the ball joint is split from the hub carrier move carrier out of the way. You could use a trolley jack handle as a prop for the hub carrier under the track rod end bolt. | ||

| − | + | [[Image:10._Lower_Ball_Joint_Split_From_Hub_Carrier.JPG]] | |

| − | |||

Step 10. Turn the steering wheel to full lock to move the hub carrier out of the way, so you can fit a ball joint removal tool. | Step 10. Turn the steering wheel to full lock to move the hub carrier out of the way, so you can fit a ball joint removal tool. | ||

| − | + | Remove the ball joint rubber dust cover and circlip. This is important because the dust cover and circlip can bind up in the ball joint removal tool and the bolts could snap when you are tightening them. | |

| + | |||

| + | [[Image:11._Steering_Wheel_Set_To_Full_Lock.JPG]] | ||

| + | |||

Step 11. Assemble the ball joint removal tool and make sure that you coat the bolt threads with plenty of copper grease. This is an Elise Parts ball joint removal tool. | Step 11. Assemble the ball joint removal tool and make sure that you coat the bolt threads with plenty of copper grease. This is an Elise Parts ball joint removal tool. | ||

| − | + | [[Image:12._Ball_Joint_Removal_Tool_Assembled.JPG]] | |

| − | |||

| − | + | Step 12. Using a 19mm socket/ratchet, tighten the bolts 2 turns each keeping them even. | |

| + | |||

| + | [[Image:13._Removing_Ball_Joint.JPG]] | ||

| + | |||

Step 13. The ball joint pops out very easily. | Step 13. The ball joint pops out very easily. | ||

| − | + | [[Image:14._Ball_Joint_Removed.JPG]] | |

| + | |||

| + | |||

| + | Step 14. It is a good idea to put new ball joints in the freezer for a day or two. This ensures an easy fit into the wishbone. Grease the rubber dust cover so that it does not snag. | ||

| − | + | [[Image:15._Greasing_New_Ball_Joint_Rubber.JPG]] | |

| − | |||

Step 15. Hand fit the new ball joint into the wishbone. It should go in easily if it is frozen as it will be slightly contracted. | Step 15. Hand fit the new ball joint into the wishbone. It should go in easily if it is frozen as it will be slightly contracted. | ||

| − | + | [[Image:16._Fitting_New_Ball_Joint.JPG]] | |

| + | |||

Step 16. Fit the ball joint assembly tool and hand tighten the bolts making sure everything is evenly spaced. | Step 16. Fit the ball joint assembly tool and hand tighten the bolts making sure everything is evenly spaced. | ||

| − | + | ||

| + | [[Image:17._Ball_Joint_Assembly_Tool.JPG]] | ||

Step 17. Tighten the bolts two turns at a time until the ball joint is seated. The heat created during fitting will defrost the ball joint. | Step 17. Tighten the bolts two turns at a time until the ball joint is seated. The heat created during fitting will defrost the ball joint. | ||

| − | + | [[Image:18._Ball_Joint_Fitted.JPG]] | |

| + | |||

Step 18. Now it is time to remove the lower damper bolt using a 17mm socket and open/ring spanner. | Step 18. Now it is time to remove the lower damper bolt using a 17mm socket and open/ring spanner. | ||

| − | + | [[Image:19._Removing_Lower_Shock_Mount.JPG]] | |

| + | |||

Step 19. Followed by the upper damper bolt. You will notice that the brake hose is straining in this photograph and I had to reposition the caliper so that the strain was removed from the hose. | Step 19. Followed by the upper damper bolt. You will notice that the brake hose is straining in this photograph and I had to reposition the caliper so that the strain was removed from the hose. | ||

| − | + | [[Image:20._Removing_Upper_Shock_Mount.JPG]] | |

| + | |||

Step 20. The assembly is now off the car and is waiting for the spring to be removed. | Step 20. The assembly is now off the car and is waiting for the spring to be removed. | ||

| − | + | [[Image:21._Shock_Assembly_Removed.JPG]] | |

| − | |||

| − | + | Step 21. In this photograph, the spring is compressed using compressors designed for bigger diameter springs. These work o.k. but more appropriate spring compressors can be purchased. Once the spring is compressed enough the bottom spring plate can be removed. | |

| + | |||

| + | [[Image:22._Removing_Spring_From_Damper.JPG]] | ||

| + | |||

Step 22. If you use oversize spring compressors you will need to unclamp the compressors to remove the spring from the damper. | Step 22. If you use oversize spring compressors you will need to unclamp the compressors to remove the spring from the damper. | ||

| − | + | [[Image:23._Spring_Removed_From_Damper.JPG]] | |

| + | |||

| + | |||

Step 23. Here is the new damper alongside the old one ready for the spring to be assembled. | Step 23. Here is the new damper alongside the old one ready for the spring to be assembled. | ||

| − | + | [[Image:24._Spring_Ready_To_Be_Fitted_To_New_Damper.JPG]] | |

| + | |||

Step 24. Fit the spring to the new damper using the spring compressors. | Step 24. Fit the spring to the new damper using the spring compressors. | ||

| − | + | [[Image:25._Fitting_Spring_To_New_Damper.JPG]] | |

| + | |||

Step 25. Here is the spring compressed on the new damper. | Step 25. Here is the spring compressed on the new damper. | ||

| − | + | ||

| + | [[Image:26._Spring_Compressed_On_New_Damper.JPG]] | ||

Step 26. Here is the spring fitted to the damper. Take care to ensure the end of the bottom part of the spring is 180 degrees away from the slot in the bottom spring plate. | Step 26. Here is the spring fitted to the damper. Take care to ensure the end of the bottom part of the spring is 180 degrees away from the slot in the bottom spring plate. | ||

| − | + | [[Image:27._Spring_Fitted_To_New_Damper.JPG]] | |

| + | |||

Step 27. Refit the damper assembly and grease the upper bushes. Do not tighten the upper or lower bolts at this stage. Lower the jack supporting the car to it’s minimum position and jack the suspension to the measurement at step 1. This is to ensure the damper is in it’s correct position to be torque tightened. It is important to do this so the damper bushes are in the correct position when the wheel is on the ground, otherwise the bushes will be twisted. | Step 27. Refit the damper assembly and grease the upper bushes. Do not tighten the upper or lower bolts at this stage. Lower the jack supporting the car to it’s minimum position and jack the suspension to the measurement at step 1. This is to ensure the damper is in it’s correct position to be torque tightened. It is important to do this so the damper bushes are in the correct position when the wheel is on the ground, otherwise the bushes will be twisted. | ||

| Line 118: | Line 147: | ||

Torque the upper and lower damper bolts to 45 NM | Torque the upper and lower damper bolts to 45 NM | ||

| − | + | [[Image:29._Jacking_Lower_Wishbone_To_Ride_Height.JPG]] | |

| + | |||

| + | |||

| + | Step 28. With the suspension under compression tighten the lower ball joint nut to 45NM (S1 55Nm). If you only have a basic tool kit you will not be able to use a 19mm socket and torque wrench because the hub carrier will be in the way, so you will need to estimate the right amount of tightness using a 19mm ring spanner. | ||

| − | + | [[Image:30._Tighteneing_Lower_Ball_Joint.JPG]] | |

| − | |||

Step 29. The damper and lower ball joint are now fitted. Note that the caliper is now repositioned to alleviate the straining on the brake pipe back in step 19. | Step 29. The damper and lower ball joint are now fitted. Note that the caliper is now repositioned to alleviate the straining on the brake pipe back in step 19. | ||

| − | + | [[Image:31._Damper_And_Lower_Ball_Joint_Fitted.JPG]] | |

| + | |||

Step 30. You can measure the thickness of your brake rotor using a micrometer. My measurement was 24.4mm which should last until my next pad change. | Step 30. You can measure the thickness of your brake rotor using a micrometer. My measurement was 24.4mm which should last until my next pad change. | ||

| − | + | [[Image:32._Measuring_Brake_DiscThickness.JPG]] | |

| + | |||

Step 31. Refit the brake caliper and torque down to 45NM (I don’t use retaining compound on these bolts as they are frequently removed). | Step 31. Refit the brake caliper and torque down to 45NM (I don’t use retaining compound on these bolts as they are frequently removed). | ||

| − | + | [[Image:33._Refitting_Brake_Caliper.JPG]] | |

| + | |||

Step 32. Secure the brake pipe to the top wishbone. | Step 32. Secure the brake pipe to the top wishbone. | ||

| − | + | [[Image:34._Securing_Brake_Pipe.JPG]] | |

| + | |||

Step 33. Refit the road wheel and nip up the wheel bolts. Check that there is no side to side play by trying to rock the wheel at a quarter to three. | Step 33. Refit the road wheel and nip up the wheel bolts. Check that there is no side to side play by trying to rock the wheel at a quarter to three. | ||

| − | + | [[Image:35._Tightening_Wheel_Bolts.JPG]] | |

| + | |||

| − | Step 34. Lower car to the ground and torque wheel bolts to 105NM. Depress brake pedal a few times to get the pressure back. | + | Step 34. Lower car to the ground and torque wheel bolts to 105NM (S1 80-85Nm). Depress brake pedal a few times to get the pressure back. |

| + | |||

| + | [[Image:36_Torque_Wheel_Bolts.JPG]] | ||

| − | |||

This is an example of a badly leaking damper. | This is an example of a badly leaking damper. | ||

| − | + | [[Image:37._Leaking_Damper.JPG]] | |

| + | |||

Here is an alternative ball joint splitter. | Here is an alternative ball joint splitter. | ||

| − | + | [[Image:39._Scissor_Type_Ball_Joint_Splitter.jpg]] | |

| + | |||

Here are alternative coil spring compressors. | Here are alternative coil spring compressors. | ||

| − | + | [[Image:38._Alternative_Coil_Spring_Compressor.jpg]] | |

| + | |||

| + | [[Category:Suspension]] | ||

| + | [[Category:DIY]] | ||

| + | [[Category:Lotus Elise]] | ||

| + | [[Category:S1]] | ||

| + | [[Category:S2]] | ||

Latest revision as of 10:24, 7 June 2008

How to change a Ball Joint and a Damper

This procedure details how to change the offside lower front ball joint and damper assembly. The nearside front is an identical procedure and the upper front ball joints follow a similar procedure. The rear ball joint and damper replacement are slightly more complicated as they require a different method to remove the brake calipers.

Safety Notice: I did not use a fixed support to prevent the car from dropping if the trolley jack hydraulics failed when performing this procedure. It is far safer to jack up the car and then use an appropriate fixed support that cannot collapse before performing these steps.

Step 1. Measure the height of the lower wishbone. You will need to use this measurement at step 28 when you torque up the upper and lower damper bolts (later stage of this procedure).

Step 2. Loosen the bolts on the road wheel

Step 3. Jack up the car on the front jacking point using a trolley jack and remove the front road wheel.

Safety Notice: It would be much safer to use the rear jacking point to raise the car and then place a fixed support under the front jacking point and lower the jack to use the fixed support for the car.

Step 4. Remove the brake pipe clamp.

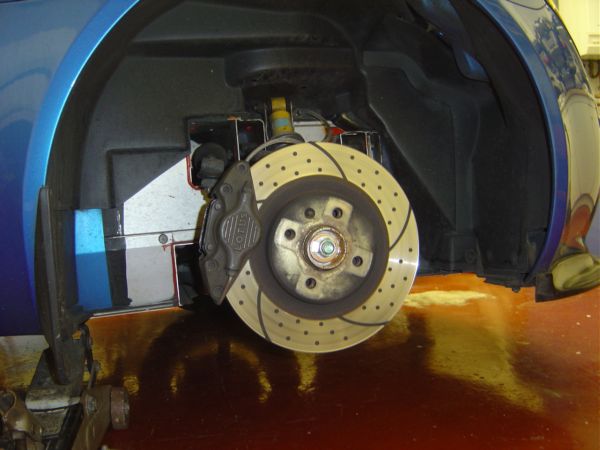

Step 5. Remove the brake caliper using an 8mm hex driver or allen key and then remove the rotor.

Step 6. Secure the brake caliper so that it does not get in the way of removing the ball joint. Ensure that the brake line is not under strain and taking the weight of the caliper. You may wish to use a cable tie to secure the caliper out of the way.

Step 7. Remove the ball joint nut . Use a 19mm ring/open ended spanner for the lower ball joint. You need to start with the ring end and transfer to the open end after winding the nut half the way up, otherwise the ring spanner will get stuck between the nut and the hub carrier and you won’t be able to remove the nut or the spanner.

Step 8. Split the ball joint from the hub carrier. You may wish to use a fork splitter with a few hard hits with a club hammer. Alternatively you could use a scissor splitter.

Step 9. When the ball joint is split from the hub carrier move carrier out of the way. You could use a trolley jack handle as a prop for the hub carrier under the track rod end bolt.

Step 10. Turn the steering wheel to full lock to move the hub carrier out of the way, so you can fit a ball joint removal tool.

Remove the ball joint rubber dust cover and circlip. This is important because the dust cover and circlip can bind up in the ball joint removal tool and the bolts could snap when you are tightening them.

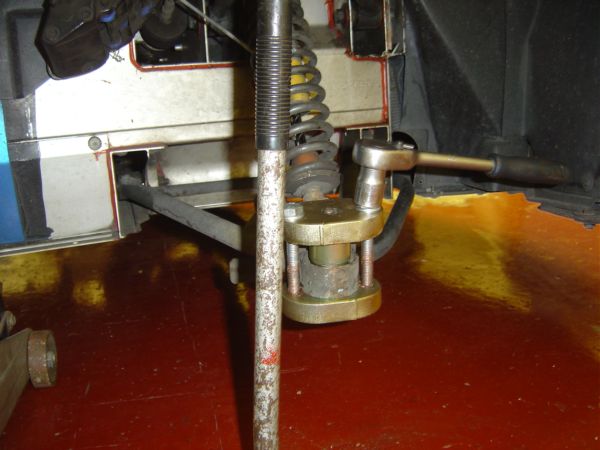

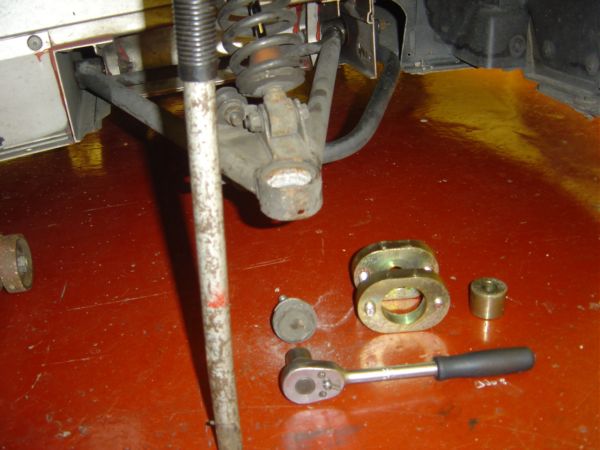

Step 11. Assemble the ball joint removal tool and make sure that you coat the bolt threads with plenty of copper grease. This is an Elise Parts ball joint removal tool.

Step 12. Using a 19mm socket/ratchet, tighten the bolts 2 turns each keeping them even.

Step 13. The ball joint pops out very easily.

Step 14. It is a good idea to put new ball joints in the freezer for a day or two. This ensures an easy fit into the wishbone. Grease the rubber dust cover so that it does not snag.

Step 15. Hand fit the new ball joint into the wishbone. It should go in easily if it is frozen as it will be slightly contracted.

Step 16. Fit the ball joint assembly tool and hand tighten the bolts making sure everything is evenly spaced.

Step 17. Tighten the bolts two turns at a time until the ball joint is seated. The heat created during fitting will defrost the ball joint.

Step 18. Now it is time to remove the lower damper bolt using a 17mm socket and open/ring spanner.

Step 19. Followed by the upper damper bolt. You will notice that the brake hose is straining in this photograph and I had to reposition the caliper so that the strain was removed from the hose.

Step 20. The assembly is now off the car and is waiting for the spring to be removed.

Step 21. In this photograph, the spring is compressed using compressors designed for bigger diameter springs. These work o.k. but more appropriate spring compressors can be purchased. Once the spring is compressed enough the bottom spring plate can be removed.

Step 22. If you use oversize spring compressors you will need to unclamp the compressors to remove the spring from the damper.

Step 23. Here is the new damper alongside the old one ready for the spring to be assembled.

Step 24. Fit the spring to the new damper using the spring compressors.

Step 25. Here is the spring compressed on the new damper.

Step 26. Here is the spring fitted to the damper. Take care to ensure the end of the bottom part of the spring is 180 degrees away from the slot in the bottom spring plate.

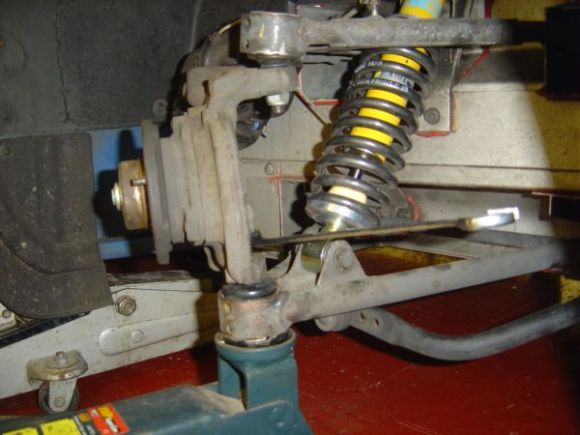

Step 27. Refit the damper assembly and grease the upper bushes. Do not tighten the upper or lower bolts at this stage. Lower the jack supporting the car to it’s minimum position and jack the suspension to the measurement at step 1. This is to ensure the damper is in it’s correct position to be torque tightened. It is important to do this so the damper bushes are in the correct position when the wheel is on the ground, otherwise the bushes will be twisted.

Torque the upper and lower damper bolts to 45 NM

Step 28. With the suspension under compression tighten the lower ball joint nut to 45NM (S1 55Nm). If you only have a basic tool kit you will not be able to use a 19mm socket and torque wrench because the hub carrier will be in the way, so you will need to estimate the right amount of tightness using a 19mm ring spanner.

Step 29. The damper and lower ball joint are now fitted. Note that the caliper is now repositioned to alleviate the straining on the brake pipe back in step 19.

Step 30. You can measure the thickness of your brake rotor using a micrometer. My measurement was 24.4mm which should last until my next pad change.

Step 31. Refit the brake caliper and torque down to 45NM (I don’t use retaining compound on these bolts as they are frequently removed).

Step 32. Secure the brake pipe to the top wishbone.

Step 33. Refit the road wheel and nip up the wheel bolts. Check that there is no side to side play by trying to rock the wheel at a quarter to three.

Step 34. Lower car to the ground and torque wheel bolts to 105NM (S1 80-85Nm). Depress brake pedal a few times to get the pressure back.

This is an example of a badly leaking damper.

Here is an alternative ball joint splitter.

Here are alternative coil spring compressors.