Difference between revisions of "Track rod end"

Digimap2000 (talk | contribs) (Added instructions for removal and refitting.) |

Digimap2000 (talk | contribs) |

||

| Line 5: | Line 5: | ||

'''Removal''' | '''Removal''' | ||

| + | |||

Loosen the locknuts on the steering arm whilst the track rod end is still attached at the wheel assembly end, this will stop it flopping around. A couple of spanners are all that's needed to back off the two locknuts one at a time. With the track rod end lock nuts released tackle the ball joint connecting it to the wheel assembly. | Loosen the locknuts on the steering arm whilst the track rod end is still attached at the wheel assembly end, this will stop it flopping around. A couple of spanners are all that's needed to back off the two locknuts one at a time. With the track rod end lock nuts released tackle the ball joint connecting it to the wheel assembly. | ||

| Line 10: | Line 11: | ||

Now put the locknut back on a few turns and tap with rubber mallet to release the joint. Remove the track rod counting the exact number of turns. | Now put the locknut back on a few turns and tap with rubber mallet to release the joint. Remove the track rod counting the exact number of turns. | ||

| + | |||

'''Refitting''' | '''Refitting''' | ||

| + | |||

Screw the track rod end back on with the same number of turns as it took to come off. | Screw the track rod end back on with the same number of turns as it took to come off. | ||

| + | |||

Reconnect the track rod end to the wheel assembly, you might need the ratchet strap again to stop the joint spinning. | Reconnect the track rod end to the wheel assembly, you might need the ratchet strap again to stop the joint spinning. | ||

| + | |||

Nip up the lock nuts against the end of the track rod. | Nip up the lock nuts against the end of the track rod. | ||

Revision as of 21:23, 8 May 2016

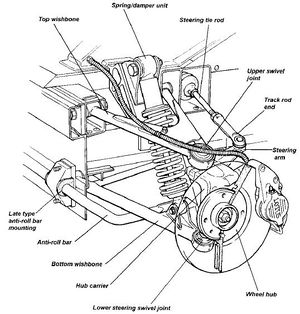

Track rod end

Removal

Loosen the locknuts on the steering arm whilst the track rod end is still attached at the wheel assembly end, this will stop it flopping around. A couple of spanners are all that's needed to back off the two locknuts one at a time. With the track rod end lock nuts released tackle the ball joint connecting it to the wheel assembly.

Give the exposed thread below the nut a quick spray with lube. If you're really lucky the nut will undo all the way with no drama, more likely it'll go a few turns then start spinning the ball joint inside it's housing. Don't attempt any of the pry bar techniques on you tube, don't try jacking onto anything, the easy technique is a ratchet strap around the track rod end and lower wishbone. Doesn't have to be all that tight to stop the joint spinning and you can remove the locknut.

Now put the locknut back on a few turns and tap with rubber mallet to release the joint. Remove the track rod counting the exact number of turns.

Refitting

Screw the track rod end back on with the same number of turns as it took to come off.

Reconnect the track rod end to the wheel assembly, you might need the ratchet strap again to stop the joint spinning.

Nip up the lock nuts against the end of the track rod.