Difference between revisions of "Pedal Box Refurbishment"

(Created page with "== SELOC how-to: Elise S1 Pedal Box Refurbishment == Firstly, Don’t. Just Don’t. Take your car and a big bundle of cash to your favourite spanner men and let them do it. ...") |

|||

| Line 38: | Line 38: | ||

With a high wear rate, and the feel of the pedal determined by that fit, I felt that a different arrangement was called for to future proof my pedal box. After all, I '''never''' intend to do this job again :) | With a high wear rate, and the feel of the pedal determined by that fit, I felt that a different arrangement was called for to future proof my pedal box. After all, I '''never''' intend to do this job again :) | ||

| + | |||

| + | |||

| + | '''My solution to the problem''' | ||

| + | |||

| + | |||

| + | [[Image:Pedal_box_diagram_2.jpg|Improved Throttle Pedal Location]] | ||

| + | |||

| + | In essence, I shortened both bearings that would normally be used so that they would fit the pedal as per the other pedals, then found a suitable larger bush to fit and use as a spacer. Because I would be manually modifying these parts, I needed some method to get a good close running fit, so found some suitable shim washers in varying thicknesses to take up the slack. I ended up using the same shim washers to take out most of the axial play in the other pedals too. | ||

| + | |||

| + | Net result is that both shoulders of the throttle pedal are properly supported, and there is a much larger bearing area on the pedal/spacer interface. Should last much longer! | ||

| + | |||

| + | '''The parts list I ended up using is below:''' | ||

| + | |||

| + | |||

| + | [[Image:Pedal_box_Table_2.jpg|Flying Banana's Parts Table]] | ||

Revision as of 10:56, 22 June 2011

SELOC how-to: Elise S1 Pedal Box Refurbishment

Firstly, Don’t. Just Don’t. Take your car and a big bundle of cash to your favourite spanner men and let them do it. Trust me on this. You REALLY don’t want to do this job. Not in a million years.

Anyone past the first paragraph will fall into one of two categories:

1. Terminally tight as a gnat’s chuff, or

2. The sort of person who has whips, nipple clamps and gimp suits in the cellar

Either way, I take my hat off to you - you are about to spend between 12 and 18 hours contorted into various unlikely positions and swearing profusely at your little plastic sports car, or “Yellow Piece of Shit”, as mine is now known.

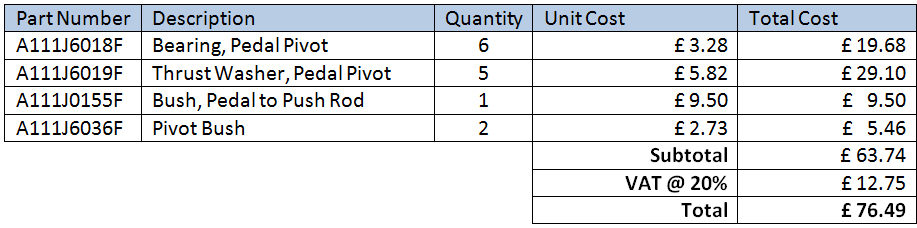

First, you’ll need the bits. The official Lotus parts are these:

This list of parts will enable you to put the pedal box back to factory fresh condition, assuming that your brake trunnion is in good condition (these appear to be good for well over 100k miles, based on anecdotal evidence). If you need the brake trunnion, it’s part number A111J0039F.

I decided that the original arrangement, particularly on the throttle pedal, could do with improvement, so designed an alternative that hopefully will last longer and does immediately improve pedal feel.

The problem with the original Lotus Pedal Arrangement

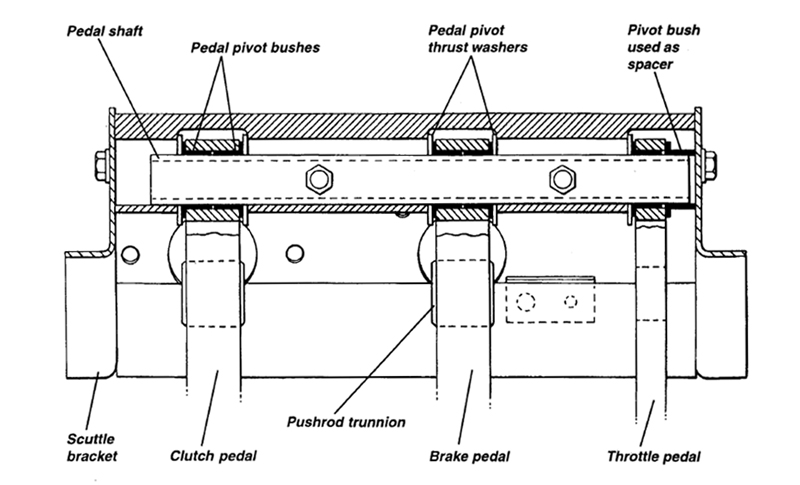

In the above diagram, you can see that Lotus used two standard pivot bearings and a single thrust washer to locate the throttle pedal. I see three issues with this:

1.Support for the right-hand face of the pedal is wholly dependent on the fit of the pivot bearing being used as a spacer

2.The pivot bearings are a running fit on the shaft, and the frictional forces involved means that the bearing will rotate with the pedal when it’s moved

3.The net bearing area where the “spacer” bush meets the scuttle bracket is tiny – these bearings are pretty thin – so the wear rate at that end of the bearing is likely to be large.

With a high wear rate, and the feel of the pedal determined by that fit, I felt that a different arrangement was called for to future proof my pedal box. After all, I never intend to do this job again :)

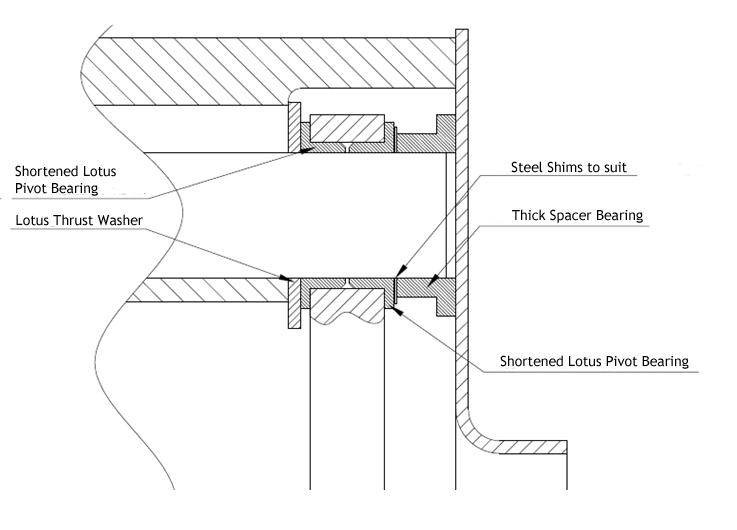

My solution to the problem

In essence, I shortened both bearings that would normally be used so that they would fit the pedal as per the other pedals, then found a suitable larger bush to fit and use as a spacer. Because I would be manually modifying these parts, I needed some method to get a good close running fit, so found some suitable shim washers in varying thicknesses to take up the slack. I ended up using the same shim washers to take out most of the axial play in the other pedals too.

Net result is that both shoulders of the throttle pedal are properly supported, and there is a much larger bearing area on the pedal/spacer interface. Should last much longer!

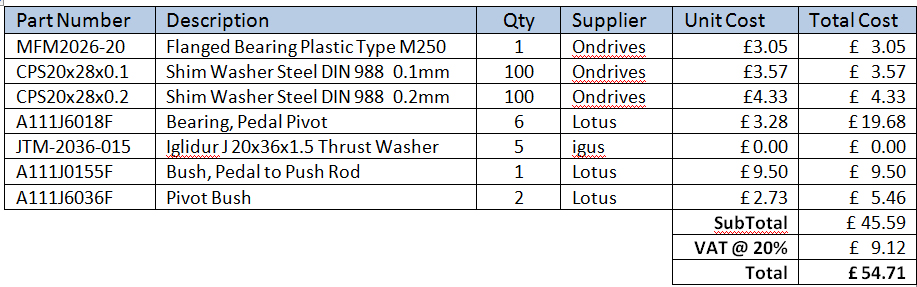

The parts list I ended up using is below: