Cylinder Head Fire Ring Peening

Peening of fire ring to eradicate porosity

By Dave Andrews

I have been asked a number of times to explain the process I use to eradicate porosity on the K series head surface.

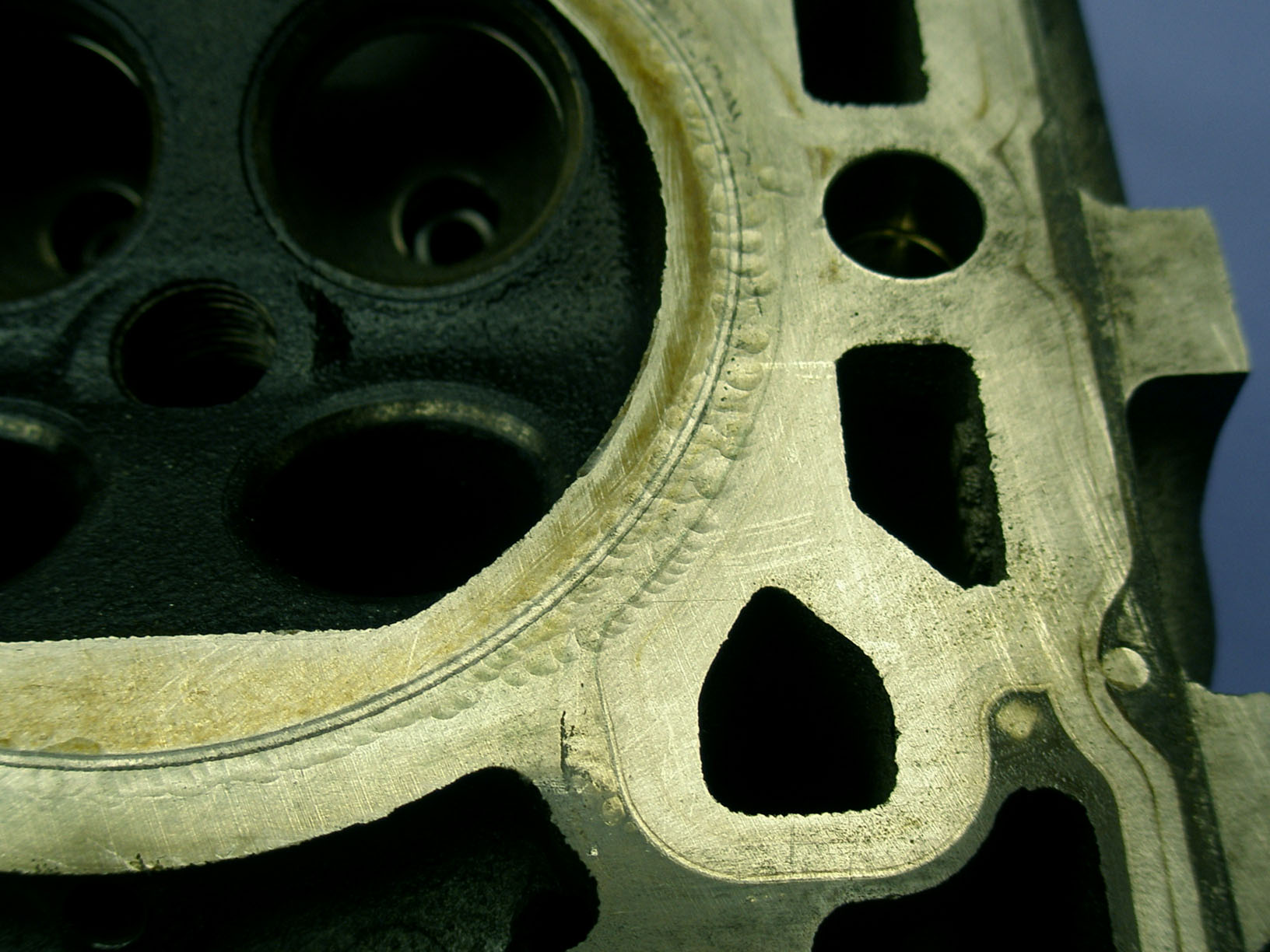

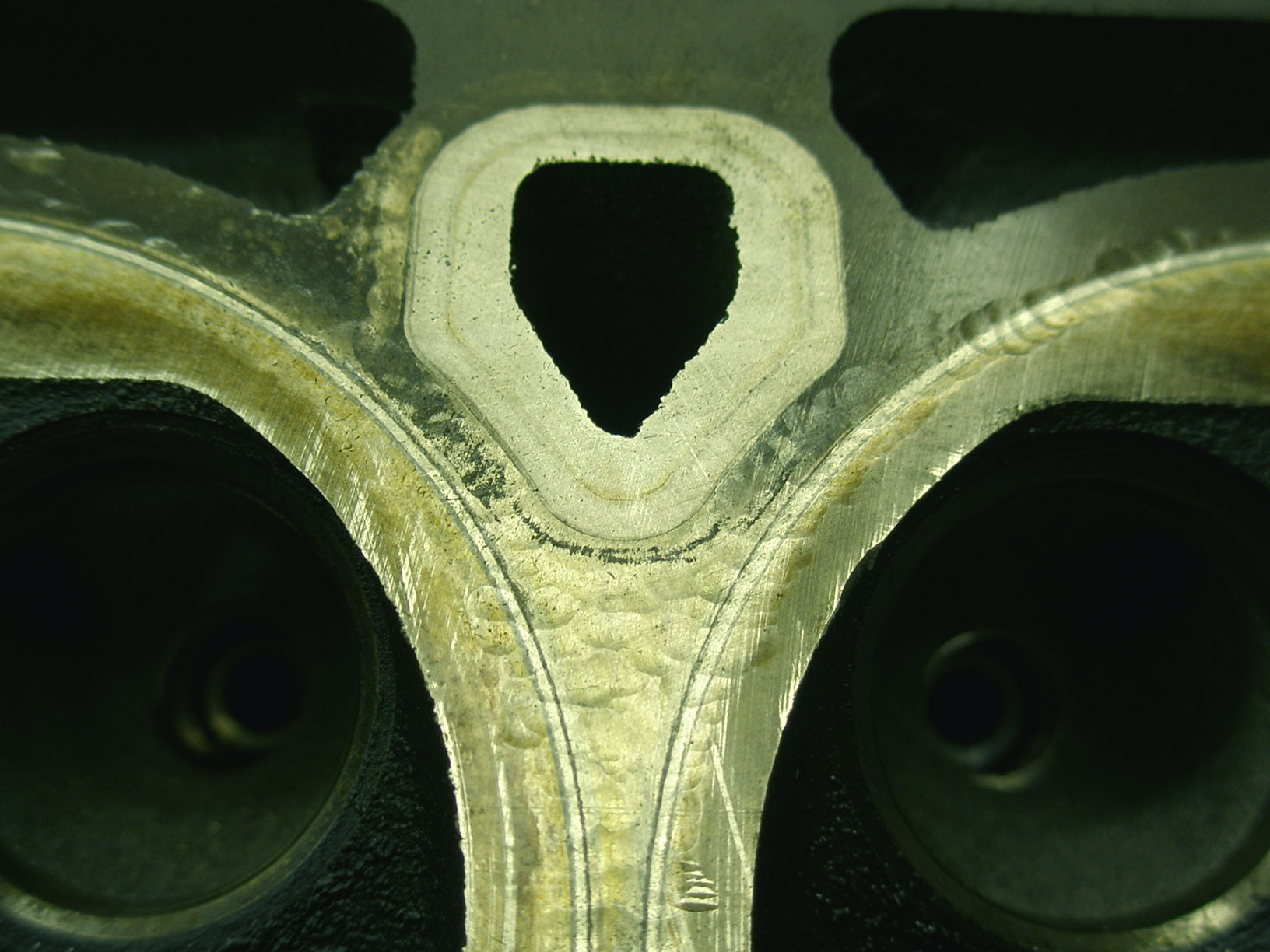

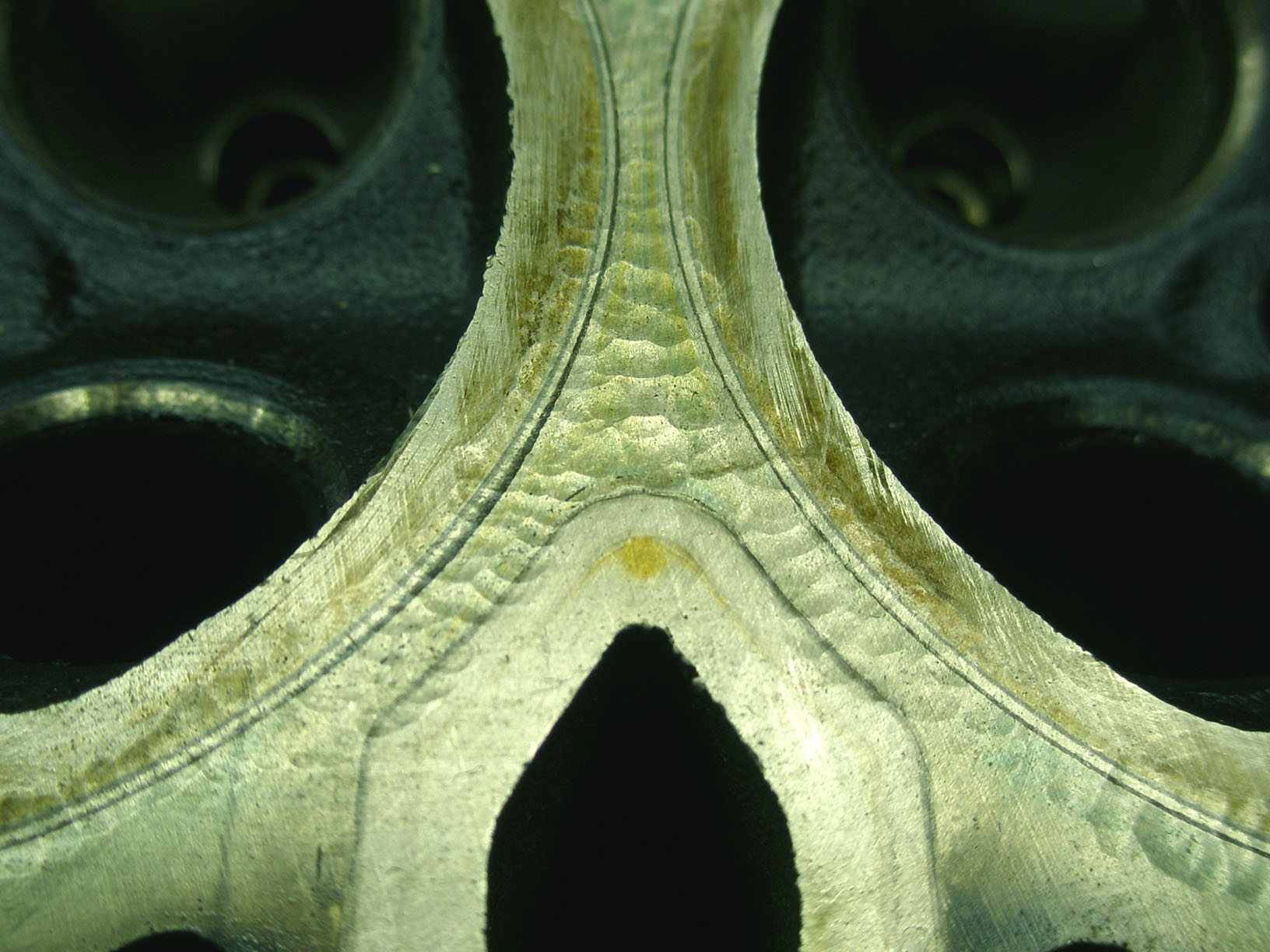

The area of the fire ring and immediate surroundings are peened downwards to compress any voids or porosity before the head is skimmed, this is akin to a cold forging process. When the head is skimmed the material where the fire ring sits is then consolidated and free of any voids or porosity, the area beneath the surface is also homogenised and should be blemish free.

This reduces the possibility of a fire ring breach due to porosity to virtually zero.

I have published below some photos, firstly the tool I use to peen the surface and also some pictures of a cylinder head surfce that has been peened.

The tool is an old exhaust valve with the head reduced and domed and the tip reduced to 4mm with the end a large radius dome shape. An old guide is tapped on to it to assist with holding the tool.