Cambelt

PLEASE ADD INFORMATION, WORK IN PROGRESS

Part numbers

For auto tensioner:

Rover pt no, LHN100560

Gates pt no. 5497XS

Piper pt no TBP33

For manual tensioner:

Rover pt no. LHN100390

Gates pt no. 5416XS

Piper pt no. TBP17 wide

Cambelt

Lotus have amended the original schedule and now recommend changing cam belts at least every four years rather than the original six, this will often mean services can become "A+belts", "B+belts", or "C-belts" depending on age and mileage and you will need to track the age of the cambelt separately from the normal service history.

Extract from Group Lotus Aftersales bulletin ...

The synthetic cam belt used on Rover powertrain Elise models is subject to age, as well as usage degradation, and will be adversely affected by any contamination with oil or coolant. In order to bring cam-belt time servicing in line with current Rover recommendations the Service Schedule for all Rover powertrain Elise models was revised in October 2003 to stipulate a cam belt replacement time interval of 4 years (54,000miles/90,000km), with an inspection every 2 years (27,000miles/45,000km). For 340R/Sport 160/Exige models, the corresponding distance intervals are 36,000miles/60,000km, and 18,000miles/30,000km.

Tensioner

PLEASE ADD INFORMATION

Auto or Manual

Changing

Fiddly but easy to do if there is a guide so I thought I would write one up.

I did this with the clam off so was easier but you can do it with it on as well.

1. Jack up right side of car (I would recommend axle stands as it is much safer)

2. Remove rear offside wheel

3. Remove right rear wheel arch liner and undertrays

4. Losen the pivot bolt and clamp bolt on the alternator

5. Loosen the small adjuster bolt on the end of the slotted bracket holding the bottom clamp bolt of the alternator. Turn anticlockwise to slacken the alternator belt.

6. Remove the alternator belt

7. Place a trolley jack under the right side of the engine and support the bottom of the engine using a small block of wood

8. Loosen and remove the 2 engine mounting bolts on the right hand engine mount. The engine should now be supported on the jack.

9. Very carefully lower the trolley jack so the engine drops about a maximum of one inch. This will enable access to the crankshaft pulley bolt and facilitate fitting the new cambelt through the gap now created.

OR

You could do the following (Thanks to Dave Andrews for the tip): You do not need to support the engine or remove both engine mounting bolts. It is perfectly possible and easier to remove one bolt at a time on the engine mount and weave the belt in between the bolts. Slacken both so that the mount drops by 12mm or so, remove the left hand bolt and push the belt in the gap between mountings. Replace the left hand bolt and tighten to where it was (I.E. 12mm gap), then remove the right hand bolt and push the belt the rest of the way through the gap, then do up the bolts. It's faster and requires no trolley jack under the sump.

10. Use a long flatbladed screwdriver to lock the crankshaft by shoving a screwdriver into the ring gear. This is visible just in front of the right-hand driveshaft at the gearbox end.

11. Use a 22mm socket to loosen the crankshaft pulley. You may need to shorten a 22mm socket to make access easier as space is a bit cramped.

12. Remove the crankshaft pulley.

13. Remove the plastic cambelt covers (top and bottom)

14. Checking the timing and fitting the cambelt. The following is only an outline guide for reference and I would suggest that you read the 'Service Manual' for detailed instructions before doing this.

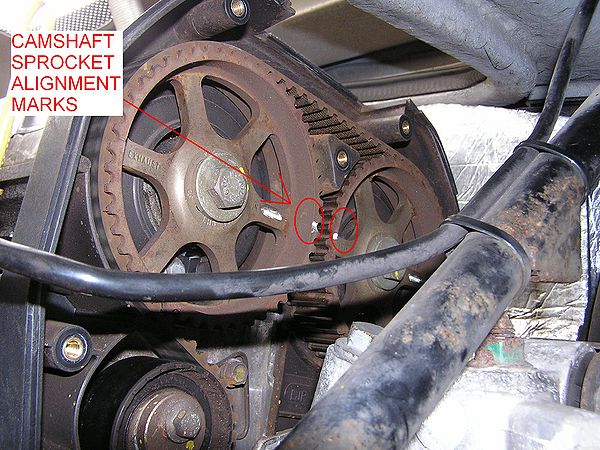

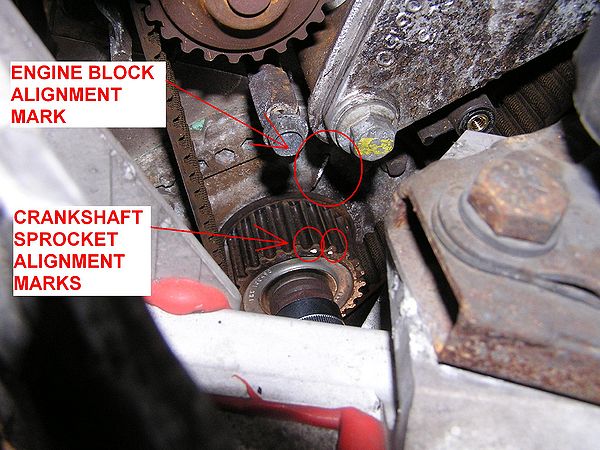

(i) There are timing marks on the camshaft pulleys and crank timing gear pulley

(ii) Line up the two arrows on the camshaft pulleys (as per the manual). Do this by refitting the crankshaft bolt (but not the pulley). You can now turn the camshafts by turning the crankshaft using a socket.

(iii) Check the position of the crank timing gear pulley as follows: Look down at the teeth on the gear at end of the crankshaft and you should see two dimples. If the timing is right these should be on either side of a vertical line cast on the engine block (flange on oil pump). These tell you that the crank is in the right place. If your old timing was out you might end up with the cams right and the crank wrong or vice versa. The most important thing is to park the crank in the right place. Now whip off the timing belt and line up the cam shafts properly (you're safe to do this only because you parked the crank in the right place - otherwise you risk piston/valve contact!) (i.e. with the arrows pointing straight across). Use a camshaft locking tool to lock the camshafts.

(iv) Now put on the new belt and adjust the tensioner. Turn the engine over two complete revolutions clockwise. Recheck all the timing marks end up in the right place. Assuming all is well, remove the 22mm bolt, and rebuild everything.

15. Refit in the reverse order following the torque specifications in the manual - about 205Nm for the crankshaft pulley, 45Nm for the cambelt tensioner pulley allen bolt and 10Nm for the tensioner backplate screw.

Useful video: http://www.mgf.ultimatemg.com/group2/engines/index.htm

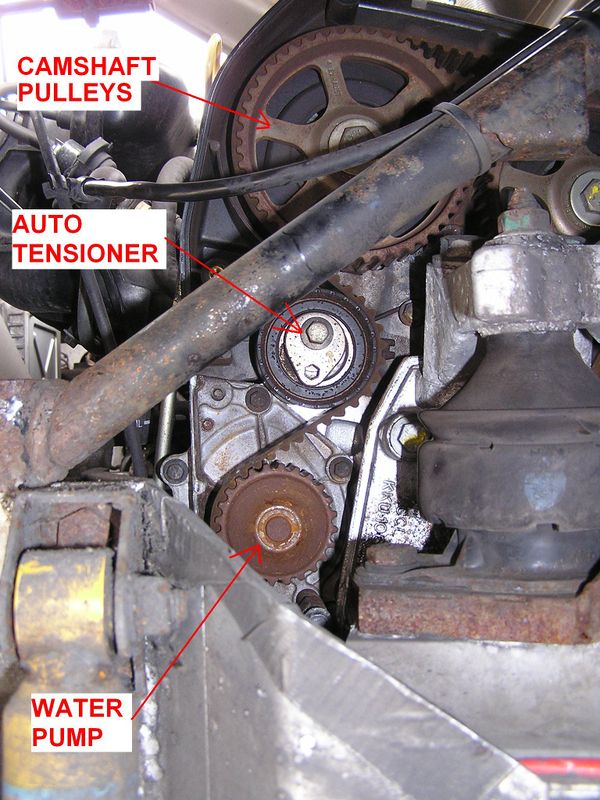

Picture Guide

From the thread here: http://forums.seloc.org/viewthread.php?tid=314945&page=1#pid5349364

1. Loads of space when you raise the rear up on axle stands. I could work on my knees with my head and shoulders inside the arch. Best access I've had in a car to change a cambelt. You can do it all by sight rather than touch. All photos were taken with me under the arch as well.

2. Space between crank pulley and car looking directly up from beneath.

3. Top cover off

4. Socket cut down with an angle grinder. I could now get this on the crank bolt with a breaker bar to undo but did have to undo the engine mounting bolts about 2-3cm to drop the engine slightly to allow my torque wrench in to do it back up (210Nm).

5. Aligning cam and crank sprockets.

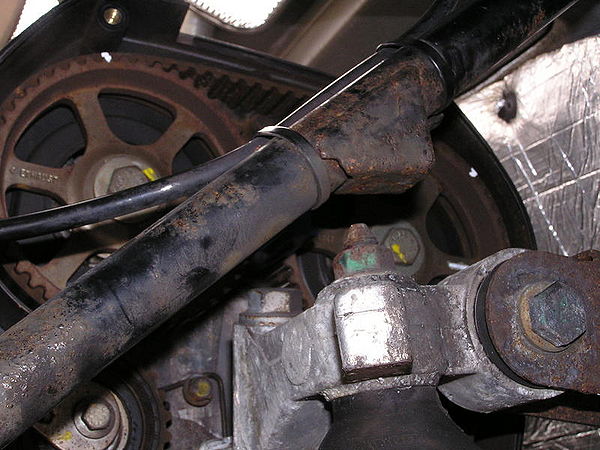

6. Lock cams.

7. Mark old belt/sprockets at both cams and on the crank - I used typist correction fluid. I transferred these marks to the new belt and that way I knew when fitting the new one I was not out by a tooth anywhere (the car will actually run with out damage when out by a tooth either way but obviously its not going to run well!!).

8. Old water pump in situ, which I replaced. Again access, I think, is great.

9. New auto tensioner. Leave the centre bolt loose to allow the tensioner to wobble a bit giving you more leeway to slide on the cam belt.

10. New belt going with marks (sorry a bit blurry).

Follow the destructions for tensioning the belt, replace lost coolant, bleed and bingo...

The hardest part was getting the top cam cover up and out of the engine bay and back in again when finished, but a bit of wiggling and it just all of a sudden fits through the gap.

Tools

PLEASE ADD INFORMATION

See Also

PLEASE ADD INFORMATION