Brake pads

The OEM Brake pads on the Elise are reasonably expensive and generally not highly regarded. There are many after market products to choose from with superior performance, both in terms of stopping power and longevity, and at a more reasonable costs.

Changing brake pads is an easy and rewarding DIY project, and some people prefer the reassurance this gives. There is a Brake pad bedding in procedure which you are encouraged to following after fitting new pads. Brake pad fitment for the Elise is as follows: https://www.youtube.com/watch?v=d2jVE1I6aBs

Early S1 Elises with MMC discs MUST use MMC specific pads, if other pads are used you will ruin the discs very quickly and also risk a dangerous brake failure.

I found a good website explaining the difference between road and race pads: https://www.lpiracing.com/store/pc/10-Things-You-Need-To-Know-About-Auto-Racing-Brake-Pads-d8.htm

Below is a list of after market manufacturers with descriptions, and real world experiences (if available), from SELOC or Lotustalk members.

Short & Simple

I added this section for people that want quick answer what to buy. It will be expanded when more information comes available.

All brake pads must meet minimal standard by law, but off course we want to blast on a twisty mountain road and this means we need something better than minimum.

Safe all round (street & track days): Mintex M1144, Pagid RS14

Trackday compounds: Endless MX72 (also MX72 plus), Pagid RSL29, Endless MA45/46b, ES88G, ES99G

Don't forget about brake fluid! https://wiki.seloc.org/a/Brake_fluid

Borg & Beck

In 2000 mainstream Automotive Products was broken up and sold, a new, smaller company was created - AP Racing. Specialised in high performance brake and clutch systems for motorsports applications. This company has since been purchased by Brembo S.p.A., but is still run as a separate entity.

You can still buy Elise/Exige brake pads and clutches branded with Borg&Beck.

user information required

https://webcat.firstline.co.uk/Home

Brembo

Brembo HP sport (HP2000)

Purpose(street/track/both): both (very street bias)

Main Brembo Manufacturer Website

Brembo HP2000 brake pads at Eliseparts shop.

Brembo HP2000 brake pads at Elise-shop.

Below information is from EliseParts.

Tested to the highest levels on the track with decelerations from 270kph (168mph) the HP2000 material is capable of operating in the most demanding conditions.

With excellent cold performance & bite, high resistance to fade, frictional stability throughout all operating conditions, reduced pad & disc wear and low dust levels, the all new HP2000 friction material offers significant advantages over its rivals. Designed to be a direct replacement for the Original Equipment (OE) pads the Brembo sport pad comes with the exact same specification as the OE pad including (where applicable): fitted wear leads, slots for separate wear leads and anti-rattle clips with the added benefit of anti-noise shims on every pad.

Combine all of this with competitive pricing and UNECE R90 approval across the full range (making them street legal) and you get a true high performance brake pad fit for the road.

Comments by vinz

On Porsche forum positive reviews about HP2000, also for track days and they get 2 to 3 days. I got these on Lotus Europa S (with ABS) to test. Feels nice, low dust, low noise, fast to bed in. On fast road - good. But during trackday on TT Assen in last session my brake pedal went long and needed to apply more force.

I rate these pads very good for fast road use (with street tires) and they do last a bit on track but not entire day.

Direct Link to Lotus Elise S2 Brembo: https://www.bremboparts.com/europe/en/catalogue/lotus-elise-1-8/000016847-1

Link to search for Brembo brake pads: https://www.bremboparts.com/europe/en

Brembo dealer/distributor/mechanic https://www.bremboparts.com/europe/en/where-to-buy

Carbone Lorraine

RC5+, RC6, RC6Es, RC8 Sintered brake pads from French manufacturer who started out as a motorbike brake manufacturer, but also does the brake pads for the TGV and works rally teams from Peugeot, etc.

RC5+

Purpose(street/both/track): Both, street bias

Lowest friction: µ=0.40

Dusting: Moderate

Pad Wear: Low

Rotor Wear: Low

Noise: Low to Moderate

Max Temp: 980C (1800F)

Bed in: The only recommended bed-in after install is to do a few moderately hard stops to seat the pads flush with the rotor face.

RC6

Purpose(street/both/track): Both, track bias

Material: Sintered Metal

Friction: µ=0.50

Dust: High

Pad Wear: Moderate

Rotor Wear: Moderate

Noise: High (after seeing video's i would say 'very high')

Watch these video's about Carbone Lorraine RC6 noise: https://www.youtube.com/watch?v=6uBug2QBpAk & https://www.youtube.com/watch?v=o7jB_OyRWo4

Max Temp: 980C (1800F)

Bed in: The only recommended bed-in after install is to do a few moderately hard stops to seat the pads flush with the rotor face.

RC6E

Purpose: Both

RC6Es is an Endurance spec: µ=0.48

Dust: High

Pad Wear: Very Low

Rotor Wear: Low

Noise: High

Max Temp: 980C (1800F)

Bed in: The only recommended bed-in after install is to do a few moderately hard stops to seat the pads flush with the rotor face.

RC8

Purpose(street/both/track): Track

Material: Sintered Metal

high friction index: µ=0.6

Dusting: High

Pad Wear: Moderate

Rotor Wear: Moderate

Noise: High

Max Temp: 980C (1800F)

Bed in: The only recommended bed-in after install is to do a few moderately hard stops to seat the pads flush with the rotor face.

RC8 compared to other pads:

To use RC8 on front brakes of a light car like the Elise would make the car lock up quickly and could be tricky.

Currently RC8 is available as a rear pad only and is used as a relatively cheap way to shift the brake balance of the car further to the rear.

RC6Es

(**) RC6Es is a specific compound which is formulated for and during the time LOT was doing the Dubai and Barcelona 24hr races. The friction level is slightly below RC6 but the compound is designed to last longer at constant (high) temperature levels. This pad is not suited for road use as it will wear discs and pads very quickly when cold. Only at the operating temperature the wear factory will become very low which means you'd be able to squeeze 24hrs of racing out of one set of pads. Specifically made for the Elise

The RC6Es compound is exclusive to elise-shop.com

It is recommended not to mix CL Brakes pads with organic pads on the car. The advantage of sintered pads is they offer their highest friction level directly from first application of the brakes where organic pads have to be warmed up to make them reach their desired friction level.

When you mix sintered with organic on the same car the brake balance would constantly shift while warming up the organic pads.

Link: Manufacturer Website

Link: Elise-shop.com are official CL Brakes distributor for Lotus applications

Link: EliseParts CL

Link: UK Distributor

Link: Dedicated CL Brakes Shop For Elise specific pads:

- Front pad type code: 4060

- Rear pad type code: 4115

Lotus has used two versions of the AP 4-pot calipers where one version came with thicker pads. When CL-Brakes introduced the 4-pot pads, they were designed for the early calipers which meant you'd have to grind 1mm of material away to be able to use them on the new calipers. Nowadays, this problem is resolved.

With standard calipers they are a straight fit but you MUST fit the small square anti rattle rubber buffers directly to the caliper or suffer very annoying rattling from the n/s/f disc.

These pads give a very consistent pedal feel and show little or no variation in retardation if temperatures go up. Fading because of pad material breakdown is virtually impossible as sintered material does not break down until >1100C and by that time your brake fluid will have started to boil.

See the following thread for some concerns:

CarboTech

1521

The Carbotech™ 1521™ is our high performance street compound. The 1521™ compound is known for its release and modulation, along with unmatched rotor friendliness. 1521™ is also a very low dusting and low noise compound with an excellent initial bite. This compound's excellent linear torque production provides incredible braking force without ABS intervention. Carbotech™ 1521™ operating range starts out at ambient and goes up to 800°F (426°C+). 1521™ is suitable for ALL street cars, perfect for your tow vehicle or fleet vehicle. Carbotech™ 1521™ is NOT recommended for ANY track use.

AX6

The AX6™ is specifically engineered for Autocross applications. A high torque brake compound delivering reliable and consistent performance over a very wide operating temperature range of 50°F to 1000°F + (10°C to 537°C+). The advanced compound matrix provides an excellent initial bite, high coefficient of friction at lower temperatures along with very progressive brake modulation and release characteristics. Many drivers use the AX6™ for street driving as well, even though Carbotech™ doesn't recommend street driving with AX6™ due to possible elevated levels of dust and noise. AX6™ is NOT recommended as a race compound in most applications. NOT FOR STREET USE!

XP8

A high torque brake compound with a wide operating temperature range of 200°F-1250°F+ (93°C to 676°C+). Carbotech™ XP8™ is the first of our racing compounds. Good initial bite at race temperatures, high coefficient of friction, excellent modulation and release characteristics. Extremely high fade resistance and very rotor friendly. Perfect for track day use with any tire and can still be driven safely to and from the track. Carbotech™ does NOT recommended XP8™ as a daily driven street pad due to elevated levels of dust and noise. Carbotech™ XP8™ is a great compound on the front & rear of most open wheel and sports racers. NOT FOR STREET USE!

Purpose: Track

Friction Coefficient: .58 to .60

Material: Ceramic

Dust: Moderate to High

Pad Wear: "Longer brake pad and rotor life"

Rotor Wear: "Longer brake pad and rotor life"

Noise: High

Max Temp: 730C (1350F)

XP10

When Carbotech™ unleashed the XP10™ to the general public it immediately gathered multiple regional, divisional, and national championships. The XP10™ has a very strong initial bite with a coefficient of friction and rotor friendliness unmatched in the industry. Fade resistance is in excess of 1475°F (801°C). XP10™ still maintains the highly praised release, excellent modulation and rotor friendliness that have made all Carbotech™ compounds so successful. Carbotech™ XP10™ is not recommended as a daily-driven street pad due to possible elevated levels of dust and noise. NOT FOR STREET USE!

Purpose: Track

Coefficient of Friction: .63 to .65

Material: Ceramic

Dust: Moderate to High

Pad Wear: "Longer brake pad and rotor life"

Rotor Wear: "Longer brake pad and rotor life"

Noise: High

Max Temp: 925C (1700F)

XP12

Another highly successful XP™ series compound with an excellent initial bite, torque and fade resistance over and above the XP10™ compound. XP12™ has temperature range of 250°F to 1850°F+ (121°C to 1010°C+). The XP12™ has that excellent Carbotech™ release and modulation that has made all other Carbotech™ compounds so successful. The XP12™ is more rotor aggressive than XP10™, but compared to the competition the XP12™ is still very rotor friendly. XP12™ is NOT recommended for use as a daily driven street pad due to possible elevated levels of dust and noise. NOT FOR STREET USE!

Purpose: Track

Coefficient of Friction: .65 to .67

Material: Ceramic

Dust: Moderate to High

Pad Wear: "Longer brake pad and rotor life"

Rotor Wear: "Longer brake pad and rotor life"

Noise: High

Max Temp: 1093C (2000F)

XP20

The latest iteration of the highly successful XP™ series of compounds. XP20™ is a step up from the highly successful XP16™ compound. With an extremely aggressive initial bite, linear torque curve and excellent fade resistance the XP20™ is another major step in progression of the highly successful XP™ series line of compounds from Carbotech™. XP20™ has a temperature range of 275°F to 2000°F+ (135°C to 1093°C+). Carbotech™ XP20™ maintains our tradition of having the outstanding release and modulation that has made all other Carbotech™ compounds so successful. Carbotech™ XP20™ is NOT recommended for use as a daily driven street pad due to possible elevated levels of dust and noise. NOT FOR STREET USE!

XP24

XP24™ is the pinnacle compound of the extremely successful XP™ Series of compounds engineered by Carbotech™. This compound is based on the same fundamentals that exist in all other Carbotech™ formulations. XP24™ has even more initial bite, more overall bite, and more torque along with the most linear torque curve we have ever offered. The thermal characteristics are of the highest Carbotech™ offers along with one of the highest coefficient of friction ratings offered by anyone in the braking industry. This compound is the longest wearing compound Carbotech™ offers as it was originally engineered for endurance applications at the highest pro racing levels. This revolutionary new compound has been extremely successful with open wheel, closed wheel, sprint and endurance applications. XP24™ has a temperature range of 400°F to 2000°F+ (204°C to 1093°C+). Carbotech™ XP24™ is NOT recommended for use as a daily driven street pad due to possible elevated levels of dust and noise along with the necessary heat required to work properly. NOT FOR STREET USE!

Bed in: XP-Series Compounds

1. All new brake pads require a bedding process, start this process by pumping your brakes a few times to assure proper installation. Once on track perform several moderate (medium) near stops (to a very slow rolling speed) to thoroughly warm up the pads and rotors. This should take 1-2 laps. This allows a thin layer of the pad material to be transferred into the micro-grooves of the rotor. 2. After the pads/rotors are warm, perform a series of hard near stops (to a slow rolling speed) until some brake fade is felt. This process should take about 2-4 laps (depending on the track). Once this occurs, then stay off the brakes (as much as possible) and bring your car into the pits/paddock to completely cool. Do not lock the tires during this operation. 3.Allow brake pads and/or rotors cool down to ambient temperatures; no less than 30 minutes. The total bedding procedure should not take more than 5-6 laps or about 10-15 minutes.

RP2

The RP2™ compound was engineered for endurance racing based on our highly successful XP™ Series formulations. RP2™ has strong initial bite, a little less modulation than our XP12™, but still maintains the rotor friendliness of our XP™ series compounds. RP2™ has great fade resistance with a temperature range of 250°F to 1450°F+ (121°C to 787°C). RP2™ is as rotor friendly as our XP™ series compounds. Carbotech™ RP2™ is NOT recommended for use as a daily driven street pad due to possible elevated levels of dust and noise. NOT FOR STREET USE!

EBC

We fit 100's of EBC Greens & have had no reported failures or catching fire. However, with any pads it is very important to bed them in properly & we supply a hanger on every car that goes out explaining this.

Edited by Sinclaire 20/05/09

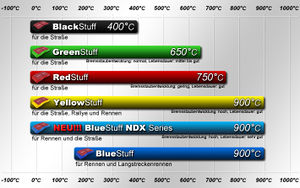

Ultimax/Blackstuff

no information found on use with Lotus. They are cheap, have the lowest temperature capacity and pure street pad. Nominal friction coefficient 0.46

Green

Not recommended for track use but comparable with OEM pads for both stopping power and wear. Nominal friction coefficient 0.55

Coefficient of Friction: .55(average) >Varies dramatically<

Material: aramid fibre

Dust: Moderate

Pad Wear: Moderate

Rotor Wear: Moderate

Noise: low

Purpose(street/track/both): Street

Max Temp: 1100 F (593 C)

Redstuff

low dust, high temp pad. Designed for large vehicles or high performance vehicles. Average friction coefficient 0.5

Coefficient of Friction: .5(average)

Material: Kevlar® fibre based brake compound enhanced with ceramic particles

Dust: Low

Pad Wear: Moderate

Rotor Wear:

Noise: ?

Purpose(street/track/both): Street

Max Temp: 1380 F (748 C)

Yellowstuff

New compound getting a good write-up for track use, possible alternative to Pagids at half the price. Cold friction 0.5 ; 550C(1000F)-0.31 ; 800C(1440F)-0.21 ; Average friction coefficient 0.5

Coefficient of Friction: .5 cold, decrease with heat

Material: Kevlar® fibre based brake compound enhanced with ceramic particles

Dust: High

Pad Wear: Moderate

Rotor Wear:

Noise: ?

Purpose(street/track/both): both (street bias)

Max Temp: 1440 (782 C)(coefficient of friction at .21 at this temp)

Bluestuff NDX

Super-Street & Trackday Brake Pads Bluestuff NDX is an intermediate grade trackday and race pad making it the material of choice for many club level racers and serious trackday enthusiasts. However, due to Bluestuff having excellent cold friction and being very controllable. More recently, EBC are pleased to announce that Bluestuff has passed extensive road focused testing and gained R90 approval on some E.U. fitments, making it unique in being the first truly track focused pad which is also perfectly legal for use on the public roads across Europe. There is no requirement for E.U. customers to inform their insurance company following fitment of R90 approved pads.

All EBC compounds are performance enhanced with CERAMIC GRANULES making them a true premium upgrade pad range for all vehicles.

Purpose(street/track/both): both (track bias)

peak friction 0.6 ; 550C(1000F)-0.45 ; 800C(1440F)-0.42

Orangestuff

In its third year of use the Orangestuff compound has proved to be a great solution for medium/longer duration race use than its famous stable-mate the Yellowstuff brake pad grade which are a great brake pad for Trackday driving.

Not road legal for EU market where R90 is required, OK for road use in USA and Asian Markets as these pads have good cold bite with progressively increasin friction as temperature rise.

Highest braking performance race compound with zero fade up to 750C.

Purpose(street/track/both): track (no R90 approval)

Cold friction 0.5 ; 550C(1000F)-0.6 ; 800C(1440F)-0.63

RP-X

Designed for vehicles driven hard on track, RP-X™ possesses a high friction level of 0.55 between 0 – 850°C and achieves 100% brake effect from cold. This makes RP-X™ an excellent choice for sprint racing or hill climb events, where full brake performance is essential without requiring any ‘warming up’, but also makes RP-X™ well suited to any type of circuit use where a high initial bite and powerful brake response is desirable.

Purpose(street/track/both): track (no R90 approval)

RP-1

Designed for vehicles driven hard on track, RP-1™ possesses a moderately high friction level of 0.45 between 100 – 750°C. The more progressive response characteristic of RP-1™ makes it well suited for inherently ‘over-servoed’ vehicles where a softer pad material is desirable to allow greater finesse when on the brakes.

Purpose(street/track/both): track (no R90 approval)

Additional Info

Bits and pieces of knowledge I found and gathered from other forums and/or websites while researching:

EBC keeps updating their compounds but name stays the same. This makes it hard to get accurate real-world data.

They had a crisis of sh*t pads back in the mid-'00s. Since then, things have improved dramatically. It takes a very short time to destroy a good reputation, and ages to rebuild it.

Andy Freeman (owner of EBC), quote from 2011: "Redstuff is now in its SEVENTH formulation reblend and may change again, every time we get feedback or new ingredients come out we add them in to the blends and re test.

Other quote's from him (2008): "Latest Yellowstuff is DM 1793 and DM 1846 which has been around for a year and is used on all UK Police chase cars and race use and adopted by Silverstone on their Elise's and Porsche fleet yet is fully streetable and a brilliant pad. The 1846 is fine for street but track work should always now use the 1793 version and that is what Silverstone use."

(motorcyclist) High iron-content discs don't like EBC pads

(comment from 2007) One of the [comments] about EBC from forum from a user (Simon S) that has used a lot of brake pads:

"EBC *anything* are just shite cheap crap, Greens are IMHO dangerous for anything other than light road use, Reds are not much better, and don't work well when pushed hard (as in overheat and break up), Yellows are rock hard and just do not offer the same level of retardation and pedal feel the OEM pads to when push come to shove... they also crumble when really pushed (and I had them actually catch fire!)."

My own experience with Greenstuff (2019-2020): work well on the road, but would like more safety margin when blasting at speed through on curvy mountain road for 2 hours (FYI: hitting ABS frequently). For Track use (Assen) they work about 45 minutes when fading starts and if you continue all brake power will go away completely - not recommended for (dry) track use. I would hit ABS in almost every corner. On wet track had no issue at all.

EBC Manufacturer Website

EBC direct

EBC at Elise shop

EBC at Elise Parts

Endless

A huge selection of brake pads, including some niche markets. These pads are made in Japan. They are direct competitor to ,another brake pad leader, Pagid - expect to pay for that privilege for top compounds ($300 to $400 per axle).

Part No. Front/Rear: EIP123/EIP124

ES Series

ES88G / ES99G Use for: Endurance Racing

CCD Series

Attack / Pace / Race Use for: Ceramic Discs

MA Series

MA35B / MA45B / MA46B Use for: Endurance Racing

SP Series

N28SP / N36SP / N37SP / N38SP / N98SP / N100SP / N105SP Use for: Rally & Racing

S Series

N99S / S89F / S90F / S91F / S93F Use for: Racing

ME Series

ME20 / ME25 Use for: Rally & Racing

N Series

N35S / N40S / N45S / N60Z Use for: Rally & Racing

SE Series

SE61H / SE63H Use for: Racing

TR Series

TRZ / TRZ-S Use for: Trackdays and Agressive Street

Special Series

DriftX / DriftX Pro Use for: Drifting & Gymkhana

Street Series

MX72 / PC / SSM Use for: Fast street driving

Additional info:

MX72

Friction=0.4-0.5

Purpose: Both, track bias

Material: Ceramic Carbon Metal Compound

Dusting: Moderate

Pad Wear: Low

Rotor Wear: Moderate

Noise: Low/None (if no friction material on disc yet or if friction material removed by lots of slow speed stops and no high speed high heat stops then Noise is HIGH)

Max operating Tempt: 50ºC-700ºC ; 1300 F

- First stop performance is poor when ambient temperature is < 60 F, once disc is warm (second stop) then brake performance returns.

- Good modulation, Good stopping power, have encountered Ice mode on track while using these pads. (notes/issues)

PC

Friction=0.38-0.48

Heat range=50ºC-400ºC

SSM

Friction=0.30-0.40

Heat range=0ºC-530ºC

SSXR

Friction=0.37-0.43

Heat range=50ºC-500ºC

Manufacturer website: https://www.endless-brake.info/index.php/products/brake-pads

Other link: https://endless-sport.global

Link to NL dealer : https://coordsport.nl/

UK Dealers:

- https://www.r53engineering.com

- https://www.m-sport.co.uk

- http://www.demon-tweeks.co.uk

- https://www.nengun.com/endless/brake-pads-mx72

Ferodo

DS2500 - H compound

Close in performance to a CL5 or Pagid42. None of the self destruct problems of the CL and better feel from cold than the pagids and dont go wooden in feel when part worn. Good for dust and no squeal either. Common replacement pad in mainland Europe. Consistent coefficient of friction (0,42) at all temperatures.

DS3000

Race pad (not suitable for the road). Very grabby (high initial bite like it says on Ferodo website), no pedal feel, non-linear (unvarying torque output). Very High coefficient of friction (0,54) at all speeds and temperatures. There are several flavours of DS3000 pad: DS3000-R,DS3000-E,DS3000plus-M

Additional brake pads from Ferodo. Not available for Elise owners: DS4003, DS2.11 (source: http://www.compfriction.com.au/brake_pads/ferodo_racing.php)

DS1.11

Based on 'ceramic' technology upon a chemical family known as Siloxanes. Unlike carbon based materials, siloxane chains doesn't decompose at high temperatures and so DS1.11 keeps on working up to the highest temperatures a brake pad could ever see.

Heavy duty endurance material. The performance remains exactly the same throughout the pad's life. It is formulated to provide a very flat friction profile at a medium/high level of friction. The pad compression is very low, always, and so pedal travel is short and consistent.

Average friction coefficient 0.46 over working temperature range of 200°-700°C

DS1.11 is meant for competition use

Bedding of Ferodo High Performance Tuning Pads

Home » Products » Car Tuning » Bedding of Ferodo High Performance Tuning Pads

A series of applications, building from light pressure (x 5 applications) to medium pressures (x5 applications) on a quiet road from slow (initially) to moderate speeds.

The applications should not be separated from each other by more than 30 seconds. There is no need for the vehicle to come to rest on each application.

Allow the brakes to cool (this will occur during normal driving anyway, but do not, for example, go straight into a steep hill descent as the first use of the brakes) and the pads will be bedded.

source

Ferodo Manufacturer Website

Ferodo at Elise Shop

Ferodo at Elise parts

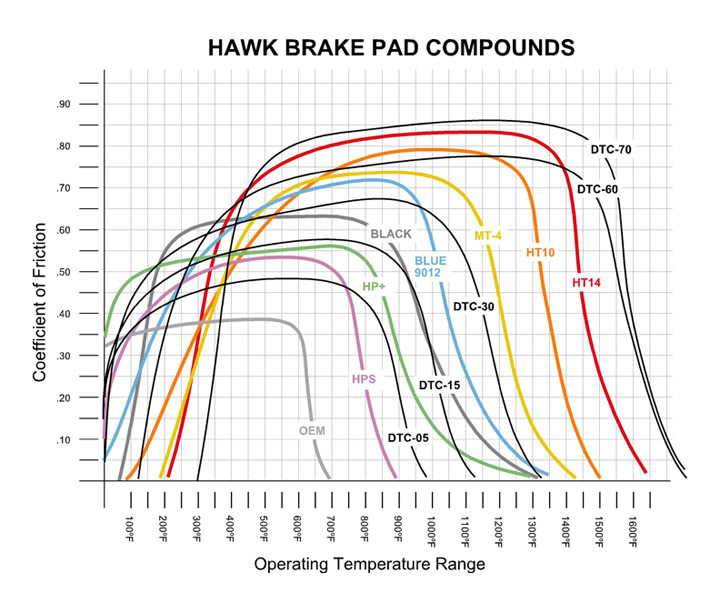

Hawk

| Hawk Manufacturer Website

According to their catalogue they only produce Lotus brake pads/discs for Elise 2001-2011 and Exige 2010-2011 (need more info: is this pad compatible with more years?)

User information required

Code reference:

- HB180?.560 Front brake pads

- HB278?.465 Rear brake pads

Instead of ? fill in compound code:

B=HPS 5.0, E=Blue 9012, F=HPS, G=DTC-60, N=HP Plus, R=High Performance street/Race, S=HT-10, U=DTC-70, W=DTC-30, Z=Ceramic Brake

note: digging through all documentation I found values inconsistent. Even if °F or °C was noted, it wildly varied. Example: HPS 100-1200°F (converted: 37.8-648.9°C) operating temperatures in one pdf and in other was 100-500° (not mentioned if it was °F or °C - I don't make assumptions when it comes to safety). I used this document and this one has different values of same brake pads in same document: http://www.hawkperformance.com/sites/default/files/downloads/HAWKBRAKEGUIDE_FINAL_2.pdf

HPS 5.0

Compound code B; 100-1200°F operating temperatures

Blue 9012

Compound code E; 250-1000°

Blue 42

Medium torque pad developed specifically for road, rally and circle track racing

This medium torque pad was developed as the next generation of the legendary Blue 9012 from Hawk

Wide operating range from 100° to 1000° F—optimal range of 250° to 700° F

HPS

HPS Ferro-Compound

(comment on other non-lotus forum)

On the street don't work well from cold.

They were so bad in 40-50 degree weather when new that I could hardly prevent the car from creeping forward just from the engine idling with the automatic transmission in Drive. And the first couple of brake applications were scary also. Almost no stopping force, like the brakes were wet. They did get noticeably better after they broke in, but they never inspired confidence on the street. It was hard to get the ABS to engage, and in testing hard/panic stops it always felt like the first maybe 40 feet weren't slowing you down much, just warming up the pads. You could feel the change in braking force while slowing down just from the pads warming up. And then after 1 or 2 hard brake applications they got a bit grabby.

Compound code F: 100-700°F operating temp

HP Plus

Key Features:

Extremely High Friction Output

Fade Resistant

Worthy for Autocross & Club Racing Events

Warning! Due to the dramatic friction levels produced by this product to achieve “race-level” braking, rotor wear, noise, dust, and pad life may be affected.

Compound code N: 100-800°

Street/Race

Compound code R: 100-1200°F operating temp

HT-10

HT-10 pads are intended for track use only. If you try to use them on the street they’ll be far below their operating temperature range and will eat your rotors and make a lot of noise.

Compound code S: 300-1300° ; race pad

DTC-60

Compound code G: 400-1600° ; DTC Series pads intended for track use only—not recommended for street use

DTC-70

Compound code U: 400-1600° ; DTC Series pads intended for track use only—not recommended for street use

DTC-30

Compound code W: 100-1200° ; DTC Series pads intended for track use only—not recommended for street use

Ceramic Brake

Excellent stopping power in an ultra-low dust, low noise ceramic compound! Not intended for track use.

Hawk Performance has introduced a premium, high performance, ultra-low dust, low noise compound called Performance Ceramic.

Performance Ceramic is engineered to reduce brake NVH (Noise, Vibration and Harshness), creating a quieter performing brake pad. Furthermore, the ceramic brake pad formula has a linear friction profile that allows your ABS brake system to work more effectively. With Performance Ceramic you can expect reduced brake pad wear, lower dust output levels and a rotor-friendly brake pad.

Performance Ceramic – quiet, clean & fast stopping!

Compound code Z: 100-650°

Buy direct from Hawk: http://www.hawkpadsdirect.com/

Direct link to Hawk Catalogue: https://images.carid.com/hawk/brakes/pdf/catalog.pdf

| Code | Compound | Optimal Range | Min Max | Torque | Comments/Remarks |

| R | Street Race | 100°-800° | 100° 1200° | Medium | Designed to and from the track without requiring a brake pad change

Wide temp range |

| N | HP+ | 100º-600º | 100°-800° | Low | High initial bite

Designed for pavement circle track under 2800 lbs |

| B | HPS 5.0 | 100°- 550° | 100°- 750° | low | Increased stopping power compared to HPS

Gentle on rotors |

| F | HPS | 100°- 500° | 100°- 700° | low | High friction/ torque hot or cold

Gentle on rotors |

| Z | Ceramic | 100°- 450º | 100°- 650° | low | High friction/ torque hot or cold

Gentle on rotors |

| Y | LTS | 100°- 500º | 100°- 650° | low | Designed for brake systems found on full-size trucks

Gentle on rotors |

| P | Super Duty | 100°- 550º | 100°- 750° | low | Designed for brake systems found on full-size trucks

Extremely high coefficient of friction and fade resistance |

Mintex

1144

Excellent value for fast road and occasional track. Quick to bed in and work well from cold. Good pad life and not particularly abrasive on disks, although can be a bit dusty. Some fade experienced after pro-longed track use. Squeal can be a problem when the pads are hot, but a hefty dollop of coppaslip on the back of the pads should help.

Can overheat on tracks that need heavy braking and not much opportunity for cooling (e.g. Brands Indy), leading to a "gravelly" feel after a few laps.

Mintex variations

Be aware that there has been some confusion over which pads are 1144's. The part number for Mintex Pads for the Elise are MDB1890 and MDB1891 (Front and Rear), there are then compound types of which 1144 is one. These are the variations;

1109 - Standard Road Use - Not suitable for the track - These are normally found in motorfactors or ebay for £25 per axel and sometimes mis-sold as 1144's.

1144 - Fast Road / Normal Track Use - Cira £60 per axel, will be marked C-Type on the box.

1155 - Hard Track use only - harder compound and will lose out on feel and progression

The code will be on the back of the pad.

Mintex Manufacturer Website

Mintex at Elise Parts

OMP

Found on on VX220 forum msg that OMP has stopped production [more information needed]

Road&Sport

OT/7951 Front pads

OT/7954 Rear pads

http://www.ybracing.com/itemlist.html?searchquery=lotus+elise

OMP Road&Sport brake pads have been developed to offer excellent performance in fast road use.

- Excellent stability of the friction coefficient, even at the highest temperature (see graph).

- This compound is the result of 30 years experience in rallies and track racers.

- For the new car models manufactured from 10/1999 the pads are homologated according to R-90 rules.

(from VX220 Forum-translated from Dutch)

What I've noticed wih OMP brake pads is that cold bite decreases after a trackday. when warm they work fine. At MOT had to push hard to slow the test for rearwheels. Front was no problem, they were warm.

Racing

OT/6951 Front pads

OT/6952 Rear pads

http://www.ybracing.com/itemlist.html?searchquery=lotus+elise

971C RACING COMPOUND OMP 971C range of brake pads is made from a new friction material, asbestos free, having following characteristics:

- COMPOSITION: thermosetting resins with the addition of special carbon materials.

- FRICTION COEFFICIENT: very high (0.48).

- FRICTION STABILITY: uniform also during varying of the temperature in a field between 100 and 800° C (see graph).

- ANTI-FADING PROPERTIES: excellent

- MECHANICAL RESISTANCE: very high also thanks to the special structure formed by the substances present in the compound.

- TOP LEVEL PERFORMANCES in professional use (Rally, Group N).

Pads have good initial bite from cold and cope well with track use.

Could do with a little more feedback under hard braking, but don't show any signs of fading.

Like many track-oriented pads they can squeal/screech quite a bit on the street.

Low disc wear.

Pagid

RS 4-2 Blue

A medium friction racing compound with good cold friction and fading resistance up to 500°C ( 930°F).

- Work well from cold.

- Under very hard use they will fade before the RS14 compound.

- less prone to squeal than RS14's

Purpose (street/track/both): Both

Friction Coefficient: .4-.46 (cold-max)

Material: Carbon

Dust: ?

Pad Wear: Good

Rotor Wear: Good

Noise: Little to none

Max Temp: 500C (940F)

Summary, A good compromise for both Road and Track usage. Can be noisy with some disc combo's.

Fronts are lasting around 10 hard track days (20 hours) rears are lasting 40 track hard days (80 hours).

RS 14 Black

This is a medium high friction value ceramic type compound with very good modulation, high fade resistance, low heat conductivity, and a good wear rate up to a temperature of 650°C (1.200°F).

- If used as a road pad they can eat discs, however when at track temperature the wear ratio will be higher in the pad providing less wear of the disk.

- Not as effective from cold as the RS 4-2 compound.

- Very track orientated pad so whilst safe to use on the road a driver with a road only intention may well be better to look at a different compound.

Purpose(street/track/both): Track

Coefficient of Friction: .44-.54 (cold-max)

Material: Carbon Ceramic

Dust: ?

Pad Wear: "RS14, while showing a reduction in pad wear, particularly at high temperatures...."

Rotor Wear: Good(on track, otherwise eats rotors)

Noise: Squeal on street

Max Temp: 800C (1472F)

These pads can generate a lot of squeal if not used in anger on a regular basis, so while highly rated for track work, these pads are perhaps too compromised for a road car. Incompatible with a lot of discs so check compatibility before buying.

RS 15 Grey

Very high torque compound. It combines a 20% higher friction value than the RS14 with a slightly increased pad wear. Needs finesse to avoid over braking the car. Good release characteristic. Although the RS15 has a very good modulation (controllability) it might have an excessive bite for some applications, as lightweight cars or cars with boosted brakes. Applications: NASCAR, CART, F3, Touring cars, GT cars, WSC, DP, Trans Am and Rally.

Official Website

Pagid Racing Pads

Pagid Elise Shop

Pagid Elise Parts

Hella Pagid

Hella sells relabeled Pagid pads. Information I could find:

Friction Coefficient: 0.46

"Wear and coefficient of friction at over 700C brake disc temp, while maintaining equal delay at increased pedal pressure"

Source: https://www.hella.com/partnerworld/assets/documents/1316_Brake_Tes_Flyer_Pagid_EN.pdf

(Advertise) test Video: https://www.youtube.com/watch?v=6yewuh5dbfQ

Cost: a bit under 100 for both axles.

Performance Friction

New brake pad available at Eliseparts shop.

PFC Manufacturer Website

Below information is from manufacturer and other websites. user information required

81

Low Grip Asphalt and Dirt Track applications Replacing the perennial favourite 80 compound, 81 offers smooth and stable high temperature torque with excellent cold bite for the dirt and asphalt racers that demand race ready friction. 81 compound also offers quicker release for unrivaled modulation with low wear and excellent disc conditioning properties.

01

01 is one of the most popular race compounds in the PFC's arsenal. Slightly higher bite and torque for the first 2/3's of the stop than 83 compound. At the end of the stop, 01 compound has less torque scatter for improved modulation with excellent release and a flat torque curve. 01 compound is very easy on the discs with very low wear, on par with 83 compounds.

08

08 compound is one of PFC newest and have gained immediate favor in Endurance Sportscar, and GT racing due to its performance in applications where smooth initial bite is a must. 08 have a slight friction rise with temperature, excellent release and modulation characteristics, and very low abraded disc wear. In addition to its considerable performance, 08 wears the longest of all PFC pads and easily matches wear of the other competitors with much higher bite.

note: Added section below because this compound is mentioned. 83 Compound is replaced by the 81 compound.

83

Recommended for high grip and severe duty applications. This is the compound that has won more championships since it’s debut than all others. It is a perenniel workhorse in NASCAR. When it comes to slowing down under the most severe conditions, 83 compound has a tremendous history of success. Higher bite than 80 compound, with a rising torque curve to handle the most extreme conditions, along with low wear. 01, 03 and 05 compounds are steadily replacing 83 compound in most applications. It is still available in many applications and remains a viable choice nearly 20 years after being released.

Manufacturer website: http://www.performancefriction.com

Porterfield

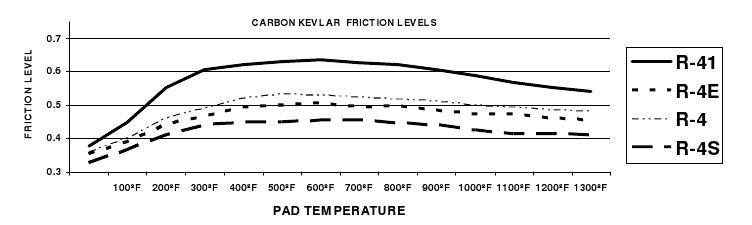

R4

Carbon kevlar brake pads for the Elise R4 race compound. The R4 is Porterfield's motorsport pad for the Elise.

Purpose(street/track/both): Track

Coefficient of Friction: .5+

Material: Carbon Kevlar

Bed in: "limited bedding procedure"

Dusting: ?

Pad Wear: ?

Rotor Wear: "rotor life extended"

Noise: ?

Max operating Temp: "450F and above"

R4-1

Vintage Compound. high friction racing material has grown to be a very popular choice for drivers who need the highest possible friction with a low pad temperature. Developed and tested in the vintage racing community

R4-S

Carbon kevlar brake pads for the EliseR4-S high-performance street compound. The R4-S is Porterfield's street-friendly version of their popular race pad.

Purpose(street/track/both): both, Street Bias

Coefficient of Friction: .4

Material: Carbon Kevlar

Bed in: "limited bedding procedure"

Dusting: Low

Pad Wear: Good

Rotor Wear: Low

Noise: Little to none

Max operating Temp: 1100 F

R-4E

Endurance Race. A Carbon Kevlar compound made to last a bit longer than the original R-4 compound.

Manufacturer website: http://www.porterfield-brakes.com/

Where to buy (USA): http://www.blackwatchracing.com/Lotus-Brake-Rotors-and-Pads-s/17.htm

UK Shop website

Powerstop

(From Powerstop website)

Trackday Spec

Recommended For Track Days & SPEC Racing Series

The difference between the checkered flag and 2nd place is measured in milliseconds. While there are many ways to shave time off your fastest lap, a brake upgrade is one of the best. For high performance cars that live on track or compete in a spec racing series, Track Day Spec brake pads can take the heat. As the official brake supplier of Bondurant Racing School, Track Day Spec brake pads are data driven and tested to provide extreme fade resistance, low thermal conductivity, and consistent pedal feel. Whether you’re a seasoned pro or just getting some weekend time on the grid, have confidence and control at every corner with PowerStop Track Day Spec.

Great For: SPEC Racing Series Link (2008 Lotus Elise): https://www.powerstop.com/product/power-stop-track-day-spec-brake-pads/#y=2008&mk=LOTUS&mo=ELISE

Rest of their compounds will not fit Lotus

Raybestos/Wilwood

While searching Lotus brake pads I came across these. Confusing is that The graph name is 'WilwoodRaybestos'. Since I don't expect anyone to buy these brake pads from Amazon this information is added for completion.

ST-41

Maintains high mu level at extremely high temperature without sacrificing good wear - both pad and rotor. Needs some heat to reach its potential. Very rotor friendly. Friction levels are just under the ST-47.

ST-43

This full race compound has proven to be one of the finest all around race compounds ever. Suitable for lightweight Formula cars up to GT racing cars in all conditions,cold or hot. Quick warmup, no rotor wear, and excellent pad life.

Purpose: Track

Friction: .65

Material: Carbon Kevlar

Dusting: High

Pad Wear: "excellent"

Rotor Wear: "low rotor wear"

Noise: ?

Max operating Tempt: 1400F

ST-45

Lower friction level than the ST-47 could be used as a great rear to compliment the ST-47 compound. This product is made-to-order and all sales are final at time of purchase. Made to order parts have a 3-5 business day lead time.

ST-47

Has the highest friction and torque available to date. It has been engineered for long-lasting extreme heat situations and maximum rotor life. If you are looking for the most advanced performing road race brake pad, that will simply out perform all the rest, this is it.

source: http://porterfield-brakes.com/images/raycomp2008_11_06_03_19_04.pdf

Link: https://porterfield-brakes.com/

SBS

Scandinavian Brake Systems. Not have the feel of Pagid but perfectly decent. High performance low cost.

- SBS Manufacturer Website

- UK SBS distributer is Questmead.

ProTrack

Steady, all round carbon ceramic race compound. Ideal for track days, standard car racing etc.

- Disc temperatures up to 700°C.

Front: 3017.CC.TH14.3 Rear: 3101.CC.

ProRace

The professional Dual Carbon race compound for racing at highest level. Stable and consistent brake performance round after round. Extremely high thermal stability.

- Disc temperatures up to 800°C.

Textar

R90 Road pads

Pure road pads which should be similar (and possibly identical) to Lotus OEM brake pads.

Additional information: OEM are Textar pads with a Brembo/AP logo printed on them. The Textar logo can be seen engraved in the backing plate.

Part numbers:

- Front: 2032306 (EAN-number: 4019722256141)

- Rear: 2041003 (EAN-number: 4019722256172)

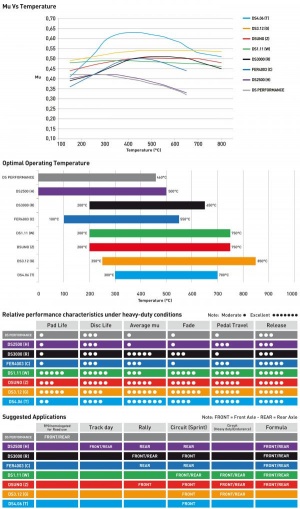

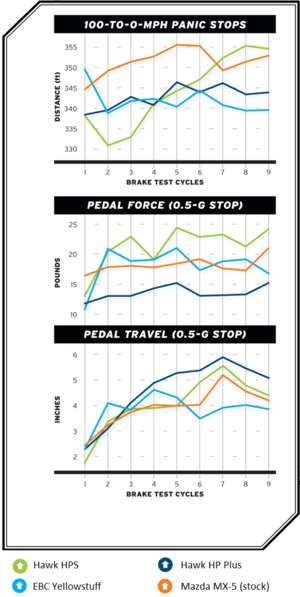

Additional Info: Brake Disc and Brake Pads compatibility & Comparision Hawk HPS, HP+, EBC Yellowstuff

Searching the web is a minefield, especially when trying to find real world data.

I did manage to find some data (although it is from an MX-5) that I would like the share here on the left.

It is hard to compare brakepads. I wish all manufactures would publish their SAE J2522 test results.

Brake Disc and Brake pads combination reference chat

While researching I came across this chart that i want to share (Chart is in German but I don't think I need to explain what green/yellow/red mean)

extra information

Extra info I found from our very own Dutch 'Arno' which I found nice to share:

In case other people are looking to try out different pads on the Elise for road racing or perhaps auto-X.

The Elise/Exige use REAR pads from a Nissan Skyline GTR at the front and the REAR pads from a Dodge Viper at the rear I simply looked them up..

DODGE VIPER 2002-92 FRONT FMSI D592 REAR FMSI D491

NISSAN SKYLINE GTR 1995-89 FRONT FMSI D639 REAR FMSI D174

So the Elise becomes:

ELISE FRONT FMSI D174/109 REAR FMSI D491

The FMSI 'D109' might be possible at the front too. Slightly thicker pad (16.5mm vs. 14.1), but same backing plate shape.

These numbers should make it possible to cross-reference with just about any brake pad manufacturer you want.