Radiator

The standard OEM Elise radiator is another weak point in the cooling system. Although it is lightweight, it has plastic end tanks which are prone to expanding and leaking under pressure.

Unfortunately you need to remove the front clamshell before you can replace the radiator.

A upgraded radiator is pretty advisable when going for Honda/Audi/Duratec engine upgrades. Most converted cars on the original radiators seem to blow them up pretty soon after conversion.

Leaks

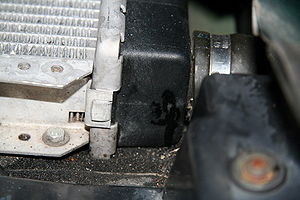

The most common fault with the OEM radiator is cracking/spliting of the plastic end tanks. The first signs of failure are drops of coolent on the windscreen, either drivers or passengers side, but castrophic failure of the end tanks has been known.

Quite often the passenger side hose is poorly connected (because it is difficult to do) and sometimes the bleed screw can leak.

The OEM radiators seem to have a problem with their manufacture where the main core is bonded to the top/bottom and leaks are all too common.

Indication of HGF

Its been suggested in the past that a blown radiator can indicate imminent HGF. The header tank cap is normally the first to vent when the system is pressurised since it only requires approximately 1 bar. The radiator is designed to operate at pressures a lot higher than this and the cap acts as a fuse. However, the header tank is on the lowest pressure point of the circuit and this allows high pressure peaks on the high pressure side (which is from the engine to the rad). need more thought here

Aftermarket Upgrades

PMA group

The original equipment manufacturer

Typically the plastic endcaps can be expected to last around 3 years

http://www.pmagroup.co.uk/branches.php

The Gloucester branch has been known to supply at £100 + VAT inc 12months warranty

Eliseparts

Eliseparts offer three radiators, the standard OEM with plastic end tanks, an all aluminium alternative and a race radiator.

Proalloy

Pro Alloy, Run by SELOC member Wayne Clayden offer a direct replacement for the standard unit: -

- Twin row 45mm thick, high efficiency alloy core.

- Aluminium end tanks,(good for high pressure systems)

- All Pro Alloy radiator cores are fully brazed in a controlled atmosphere process to comply with ISO 9001 quality assurance standards

Elise-Shop.com

Elise-Shop.com Run by SELOC member Yvo Tuk offer two radiators, the standard OEM with plastic end tanks and a Full aluminium alternative.