How to fit a concentric clutch cylinder to the Lotus/Rover Powertrain PG1 gearbox

Get a smooth and a well proven solution using a SAAB cylinder

The Powertrain PG1 gearbox of Rover origin is renowned for its strength and to be easy to work on. It was fitted to the Lotus Elise S1 but first and foremost to a lot of Rover cars.

The clutch is operated by an external hydraulic slave cylinder acting on a lever rotating a shaft. The shaft extends into the clutch housing where it swings a fork acting on a clutch release bearing. The quite long transmission route with levers, bearings and brackets underway adding flex and friction from the cylinder to the release bearing is not ideal.

Most modern cars use a concentric slave cylinder fitted around the gearbox input shaft and the cylinder acts directly on the release bearing. Swedish car manufacturer SAAB was among the first to use this simple but effective solution in mass produced cars, for instance on the SAAB 900 Combi Coupe from 1985. It was used on some Opel/Vauxhall models as well.

Likewise some gearbox companies design their racing transmissions for use of the SAAB pattern clutch cylinder.

The SAAB concentric clutch cylinder (part no 4776308) is no longer available as an original spare part but a lot of aftermarket part manufacturers still produce it. Some fabricate it with a cast iron body and others with an aluminum body, the latter being the lightest and most attractive for lightweight Lotus use.

Both AP Racing and Tilton produce similar lightweight clutch cylinders of very high quality. But with a very high price tag as well.

For my own use I have fitted and tested the Quinton Hazell clutch cylinder, part no. CSC 008, which is of the lightweight aluminum type, both on my former Lotus Elan Sprint and on my current Elise S1. In both cases the clutch pedal became lighter and the clutch grip point more consistent and well defined.

So here is a recipe for fitting the SAAB concentric clutch release cylinder to the Elise with Rover K-series engine and PG1 gearbox.

Threaded bolt holes

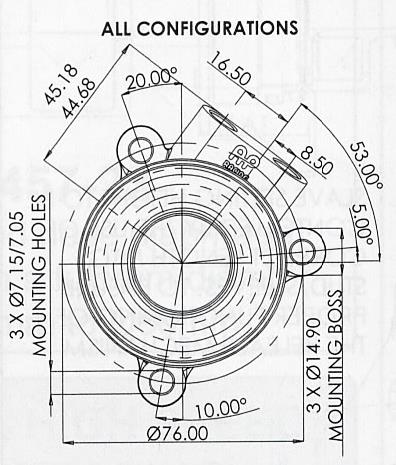

The clutch cylinder needs three M6 threaded mounting holes drilled into the gearbox clutch housing according to the drawing below.

It’s advisable to mark up the dimensions on 2 mm steel sheet and thereby make yourself a drill pattern. The centre hole should be 35 mm for the centre spigot and the three holes providing for the M6 threads should be 5 mm.

With the help of a drill press machine drill through your sheet steel drill pattern and 15 mm into the gearbox clutch housing, put a 5 mm plug through the first drilled hole fixing the pattern plate and then advance to the next hole thereby precisely fixing the holes in relation to the centre and to each other. If you know somebody with access to a CNC machining centre it will be a quick operation but if you have the skills and patience you can manage fine with simpler tools.

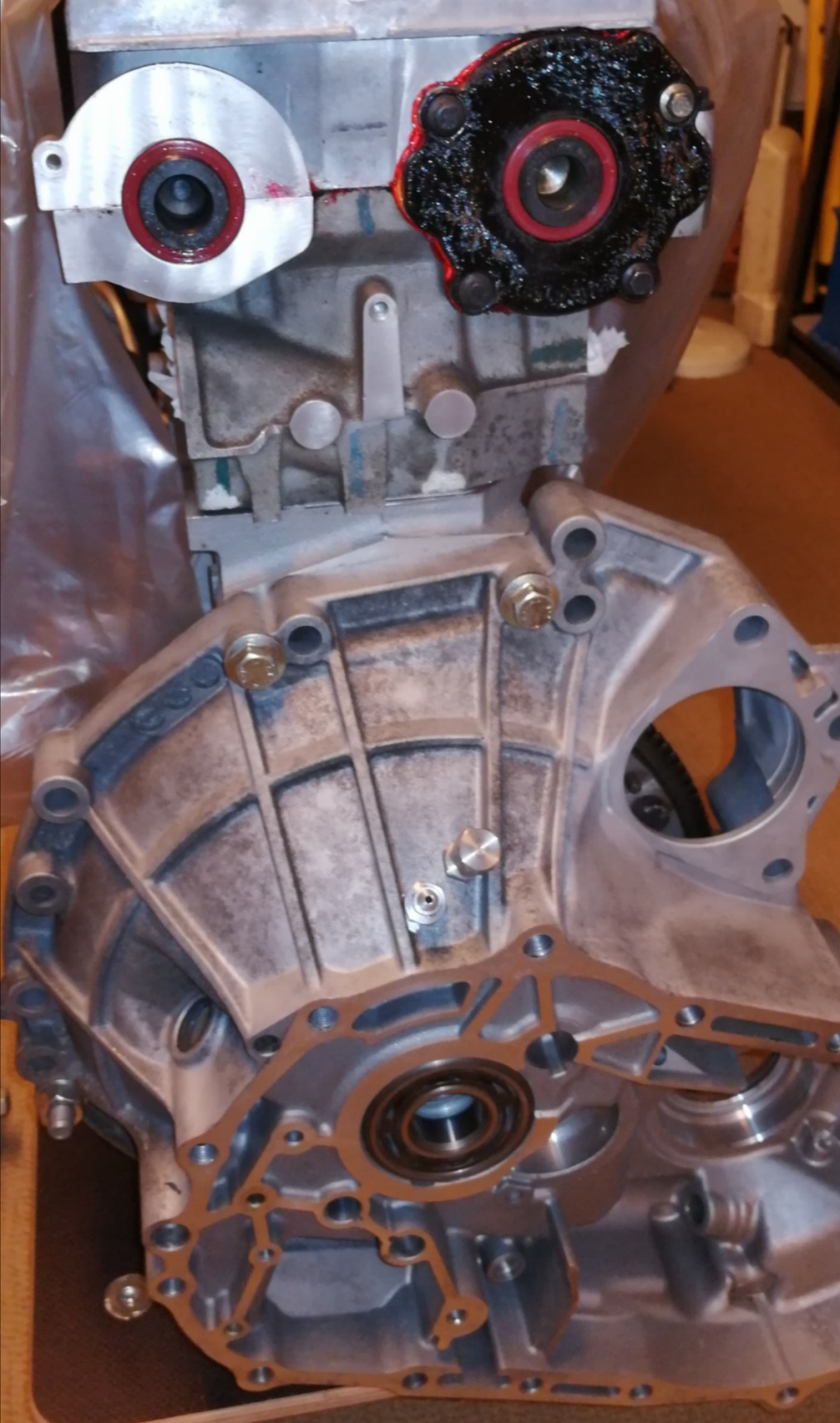

The Ø 35 mm hollow centre spigot for the old release bearing is machined down to a length of 3 mm to accommodate the new clutch cylinder.

Before drilling:

After drilling:

Clutch cylinder backplate

The clutch cylinder itself has to be disassembled. The back plate is fixed by small deformations of the Ø 59 mm edge of the aluminum. These deformations should be carefully and gently tapped back with a blunt and rounded small chisel. You can then remove the back plate.

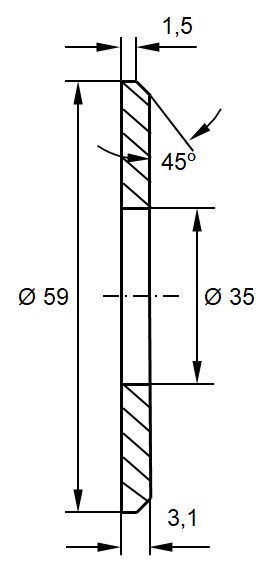

The original backplate is substituted by a fabricated one with the below dimensions to provide for centration of the clutch cylinder on the remaining Ø 35 mm spigot.

The new backplate is carefully fixed by tapping the edges of the aluminium over the 45º chamfer pointing to the rear.

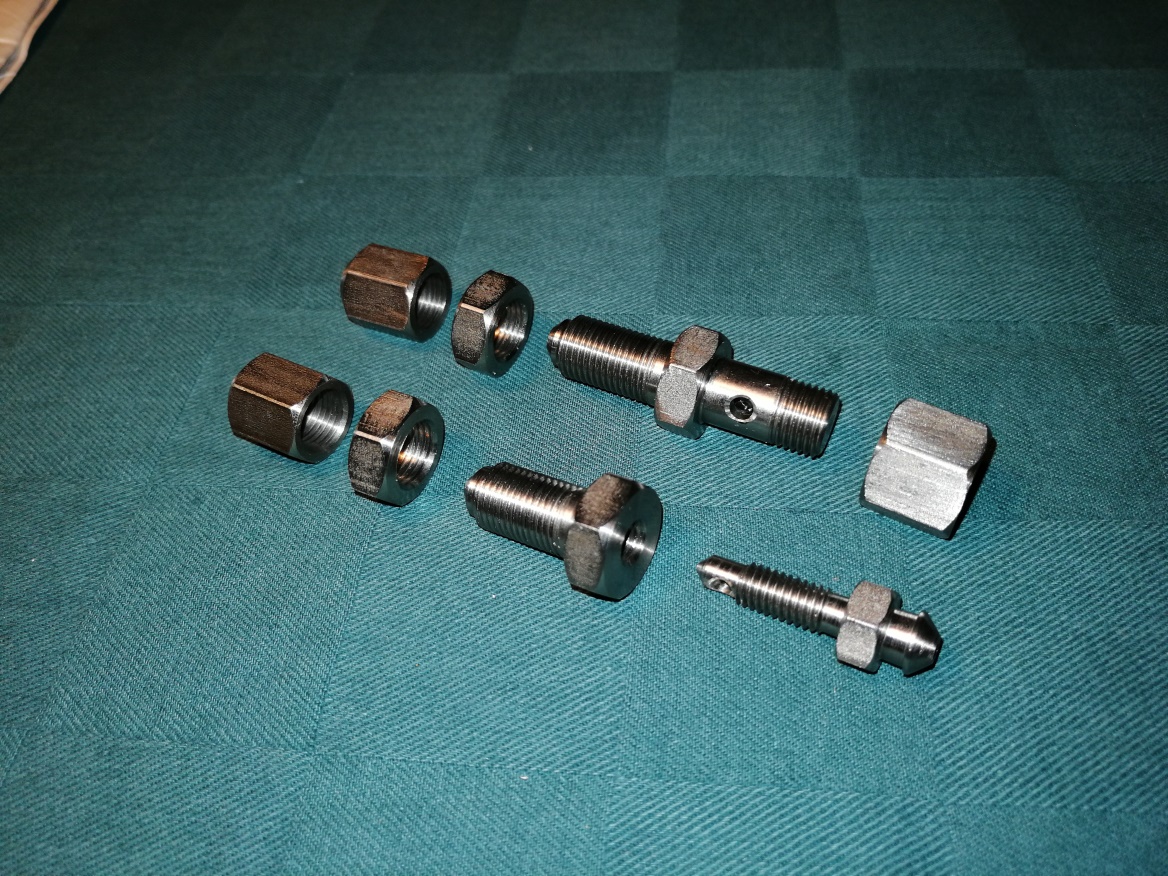

From a M6 threaded bar 3 suitable long stud bolts are cut, carefully deburred and turned into the M6 threaded holes in the clutch housing. The clutch cylinder is placed over the centre spigot and over the stud bolts. The distance between the edges of the clutch housing and the clutch cylinder back flange is measured carefully. Three long M6 nuts are cut to exactly this length and fitted over the stud bolts to provide base for the fixation of the clutch cylinder.

Ideally the backplate should be in light tension when the nuts on the front side of the clutch cylinder are tightened. Then the forces are fed into the recess at the base of the cut-down Ø 35 mm spigot and not through the three bolts.

Hydraulics

The brake/clutch fluid activating the clutch cylinder will have to be routed through the clutch housing. A bleed line pass-through should also be provided for.

The clutch cylinder has no connection for a bleed line. It’s possible to remove a small steel ball blocking a drilling, cut a M6 thread in place and thereby establish a connection for a bleed line.

You can buy suitable fittings for passing through the clutch housing. Or you can ask somebody with a lathe to fabricate some for you.

The holes for hydraulic fittings passing through the clutch housing should be drilled in places carefully selected with respect to the clutch pressure plate passing close by on the inside and to assure access form the outside as well.

So with the above relatively simple and straightforward modifications and the relatively cheap SAAB clutch cylinder you can convert your PG1 gearbox to use a modern, light, simple, reliable and well-functioning concentric clutch release cylinder mechanism.